Hi. This is my 2nd unit. 1st unit after I had time from work to buy my bottle (had to wait on the flow regulator which took another week from everlast) I finally tested it out. I called everlast and had the unit exchanged for another. After a week of waiting for the new unit to arrive today I hooked it up to make sure it was working before I went to sleep since the unit arrive at about 7pm. Still no spark. I don't know if it's me since this is my first time welding with mig or the unit. It seems pretty straight forward. It's was too late to call everlast since it was already 8pm central time. I'm starting to get frustrated because I am spending more time contacting everlast than welding.

Here are some of the pic. Stick seems to be working fine with both unit.

Stick testing 6010

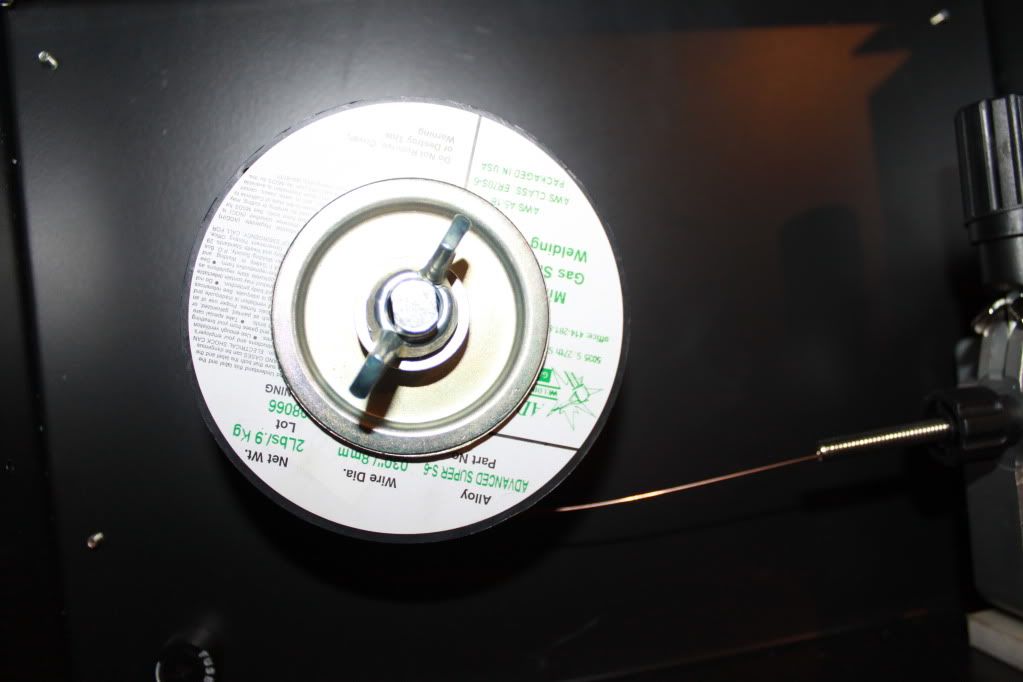

Mig

Reply With Quote

Reply With Quote