I have friends which are fond stuntriding

Оne of these days they brought to me the motor from (DUCATI) with the broken fastenings, and plaintively asked me everything to repair.

Guys any thoughts, councils

I have friends which are fond stuntriding

Оne of these days they brought to me the motor from (DUCATI) with the broken fastenings, and plaintively asked me everything to repair.

Guys any thoughts, councils

Ruslan

EVERLAST Power Tig 255 EXT

EVERLAST PP256

PC300

EWM Pico 162

MERKLE mobimig 180K

SELCO Genesis 352 pme

The PP256 should be able to weld it. Is it cast aluminum?

Mike R.

Email: admineverlast@everlastwelders.com

www.everlastgenerators.com

www.everlastwelders.com

877-755-9353 x203

M-F 12 - 7PM PST

FYI: PP50, PP80, IMIG-200, IMIG-250P, 210EXT and 255EXT.

I'd throw it over the hill.

If I were going to attempt a repair, I think I would split the cases, do a complete teardown, then machine off the mount.

I would then machine a tube with an undersized hole (so that it would not take quite as much heat as a solid bar) and try to weld the new tube in. Then re-machine the hole.

Tell them it will be at least 15000 RUB to do the job. If that doesn't scare them off, have at it.

Everlast 200DX

Everlast PT185

Shoptask 3-in-1 (not currently in my garage, but I own it...)

Any day on a motorcycle like this that ends just needing parts and labor is a good day.

4.82, 158.67mph 1/8th mile 7.350, 200.35mph 1/4 mile

It could be done. You have some parts that look like you'll need to be careful about overheating nearby. Controlling the heat soaked into those parts, will slow down the repair, but it still can be done. But you could either "vee" out the crack and re-attach the broken piece, or just build up the missing metal with filler rod and machine it down to desired surfaces afterward, (or more likely a combination of both) using AC-TIG. Either way, make sure there is no dirt or grease at the surfaces you are welding before you start joining the metal together. Check for clean surfaces with a light AC-TIG arc - when it leaves behind a white etched, surface everywhere, it means it will weld cleanly. Black crusty surface anywhere = clean those areas some more before you start welding.

-edit- check out the below threads, which may be useful for this work:

Using filler rod to "build up" a broken off aluminum casting:

http://www.everlastgenerators.com/fo...nt)-jakeru-s-9

http://www.everlastgenerators.com/fo...-TIG-build-up)

Repairing a cracked aluminum casting:

http://www.everlastgenerators.com/fo...r-(jakeru-s-5)

Limiting heat to a nearby heat sensitive area:

http://www.everlastgenerators.com/fo...e-with-He-mix)

Last edited by jakeru; 03-10-2012 at 09:16 PM.

'13 Everlast 255EXT

'07 Everlast Super200P

Thanks sportbike,jakeru

I told them approximately the same(but they speak that engine dismantling is a full ###)

from friends I don't take money,It is necessary to strain and create a miracle

I think to weld the broken out piece and to strengthen it an edge from aluminum,and to the place of a missing piece to turn the aluminum bushing, to cut it lengthwise and to try to adjust a half to a relief of a missing piece and weld all

Tomorrow I will start to conjure

Last edited by donor76; 03-10-2012 at 07:40 PM.

Ruslan

EVERLAST Power Tig 255 EXT

EVERLAST PP256

PC300

EWM Pico 162

MERKLE mobimig 180K

SELCO Genesis 352 pme

Много фотографий пожалуйста.

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw

This is weird. When I first commented there were no pictures, but I see them now and no edit on the post. Something is up with my other computer.

Anyway. You can make the repair. But if they are friends (free or cheap). Either pass on it, or make them help with the repair. It will be some work, Jake outlined what you need to do. Note what he said on the black is bad.

Mike R.

Email: admineverlast@everlastwelders.com

www.everlastgenerators.com

www.everlastwelders.com

877-755-9353 x203

M-F 12 - 7PM PST

FYI: PP50, PP80, IMIG-200, IMIG-250P, 210EXT and 255EXT.

I'm not going to lie, if it were mine I would try it! Not sure I would want to do it for someone else $$$. I could see a project like that costing me more money than I would make if I were charging. On the flip side it would be nice to know whether or not you could pull off that type of repair.

Lincoln Eagle Engine Drive

Everlast MTS 250

Everlast Power Tig 225lx

HTP Mig 2400

Everlast Power Plasma 60C --> Just need to finish my CNC Plasma Table!

Miller Spectrum 375 Extreme Plasma cutter

Victor cutting torch

HF 20 Ton Shop Press

HF 4x6 Band Saw

HF Air Compressor

Northern Tool Drill Press

www.murphywelding.com

Looks good. Is that a piece of fuel injection rail that you used for the repair piece on the left side

Did you use your Powerpro 256 welder on this?

John

Everlast 200DX

Everlast PT185

Shoptask 3-in-1 (not currently in my garage, but I own it...)

Any day on a motorcycle like this that ends just needing parts and labor is a good day.

4.82, 158.67mph 1/8th mile 7.350, 200.35mph 1/4 mile

Very nice job. Get a little dirt and grease on there and I bet you almost can not tell it was repaired.

Is the motor pinned on the frame? I do not see threads and not a bike guy? Or does a pin go all the way through?

Good question from John, did you use the PP256? 4043?

Mike R.

Email: admineverlast@everlastwelders.com

www.everlastgenerators.com

www.everlastwelders.com

877-755-9353 x203

M-F 12 - 7PM PST

FYI: PP50, PP80, IMIG-200, IMIG-250P, 210EXT and 255EXT.

Everlast 200DX

Everlast PT185

Shoptask 3-in-1 (not currently in my garage, but I own it...)

Any day on a motorcycle like this that ends just needing parts and labor is a good day.

4.82, 158.67mph 1/8th mile 7.350, 200.35mph 1/4 mile

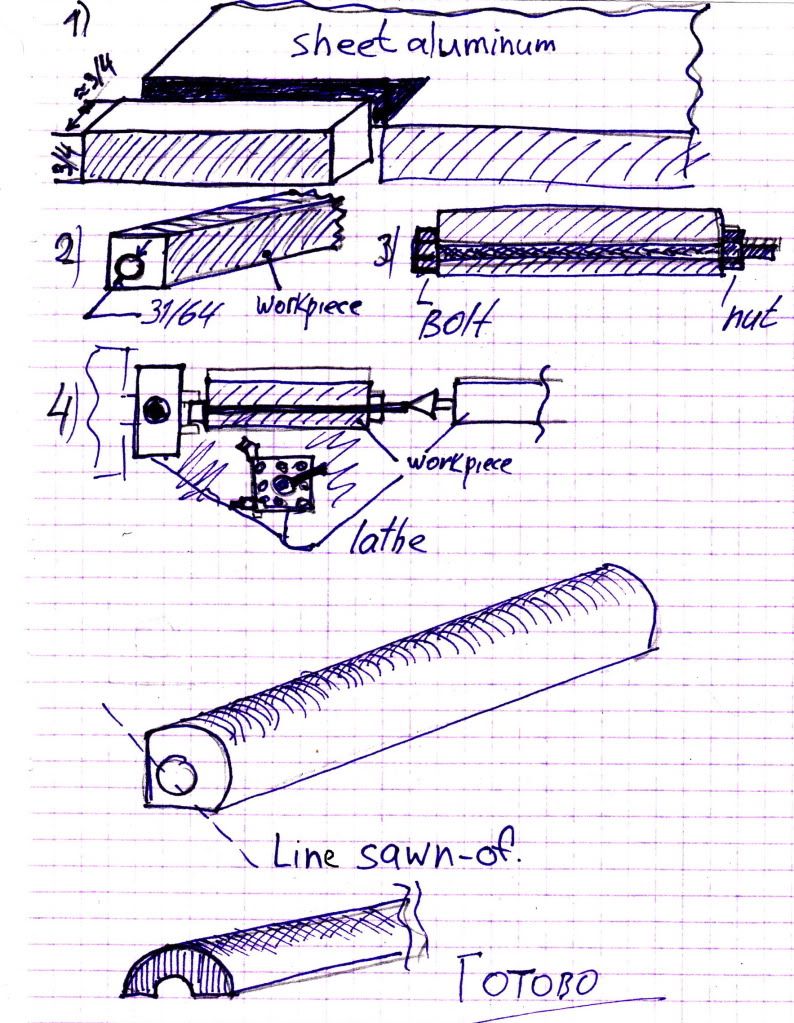

For restoration of the left part necessary to me half of bushing in diameter of 1 inch (25 mm) with an internal aperture of 31/64 inches (12.5 mm).

For economy of a material I have cut a piece of sheet aluminum in the thickness 3/4дюйма (20мм) have drilled in it an aperture with displacement, into an aperture have inserted a suitable bolt, have drawn in a nut, and all this design have processed on the lathe.After processing on the lathe workpiece has cut it lengthwise.The missing piece is ready,At welding I have passed through an aperture a rod in diameter of 31/64 inches (12,5мм) on through.

It is a pity to me that I don't know English language, and I know that to you very difficultly to understand that that I have written with the help Google translator (excuse) therefore I will support with drawing

I hope all will understand.

Mike i use the PP256 and 4043

Ruslan

EVERLAST Power Tig 255 EXT

EVERLAST PP256

PC300

EWM Pico 162

MERKLE mobimig 180K

SELCO Genesis 352 pme

Great explanation Rusian.

I can understand everything that you write. Google Translator is an excellent tool

Великий объяснений Rusian

Я могу понять все, что вы пишете. Google Переводчик является отличным инструментом

Last edited by sportbike; 03-11-2012 at 07:15 PM.

Everlast 200DX

Everlast PT185

Shoptask 3-in-1 (not currently in my garage, but I own it...)

Any day on a motorcycle like this that ends just needing parts and labor is a good day.

4.82, 158.67mph 1/8th mile 7.350, 200.35mph 1/4 mile

Nice work,,,the man who owns the bike is lucky to have a friend like you...

Some of those lies people tell about me, are true

I use this service http://translation2.paralink.com/Rus...h-Translation/ with the "compare" function to see the results of other services. My actual Russian speech is very basic... still learning.

Edit: Here is a direct link to the compare service with "back translation" http://imtranslator.net/compare/russ...lation/#window

Last edited by zoama; 03-12-2012 at 12:15 AM. Reason: Added another link

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw