Ok guys, I am officially confused.

I decided to upgrade my wiring to 6 gauge for a 50 amp breaker. I have 1 white(126v) 1 black(126v) and 1 green(ground/common?).

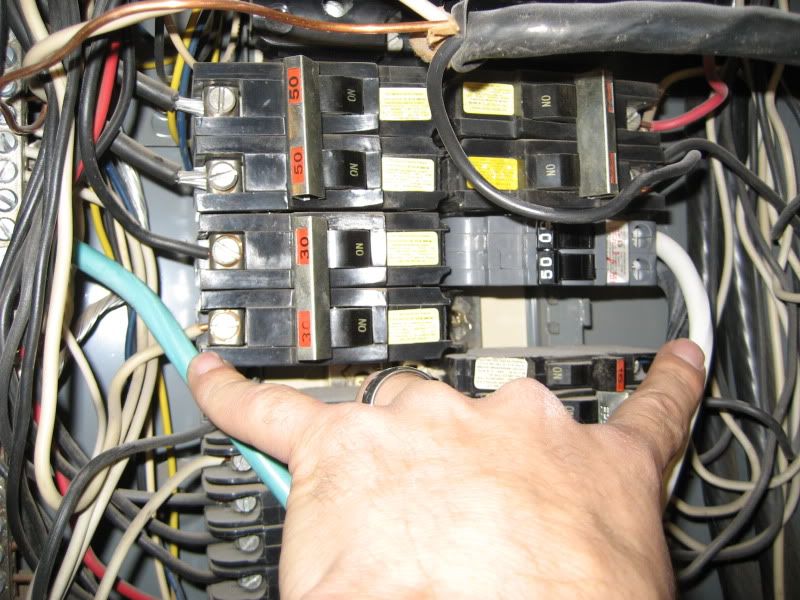

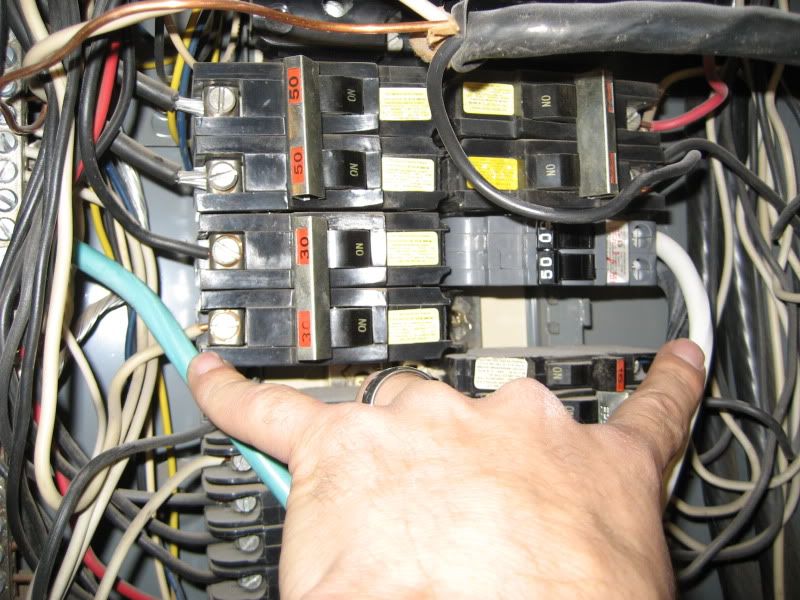

Here are the pictures of how I have it wired. And nothing is coming on. My plasma cutter doesn't come on nor my welder, but I get 126v from the ground to one leg and then another 126v from the ground to the other leg (on the outlet where the welder plugs in).

The way I used to have it wired up was essentially the exact same way with 10g wire though. Although I had 5 wires. One red(power) one black(power) and then a green a white and an orange. The last three(grn wht orng) I just twisted all together and put them in the ground plug, essentially what I have done with just the green above in the pictures. Then on the box, the org,grn and wht all went to the same ground block with their own screws. My welder and my p cutter worked just fine that way the other day until I took it all apart and upgraded wiring to this current situation.

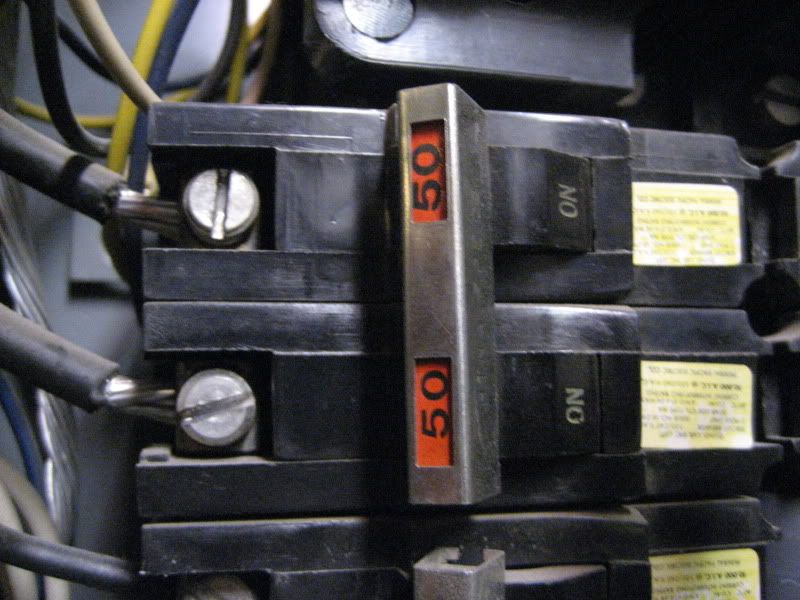

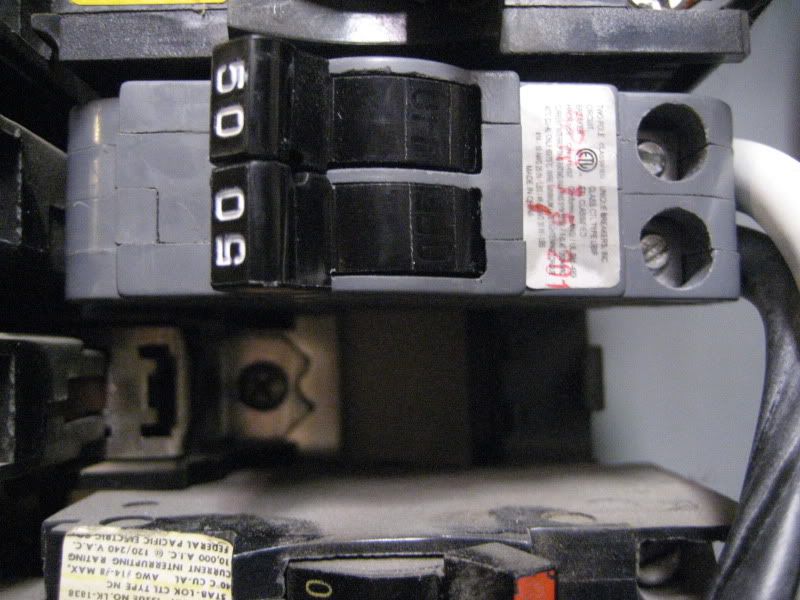

This new wiring is on a brand new 50amp breaker. I don't suspect the breaker because I am getting 126.2v X 2 (white and black) all the way down to the plug where the welder plugs in. Last time I had it wired into my 50 amp breaker that ran my stove.

Any idea's as to what is going on? Cause this is really stumping me. The only new parts are the 6 gauge cable and the 50 amp breaker. Everything else (the outlet) was working before and I have reused.

The old 50 amp breaker that I USED TO USE/tie into, you can see up in the top left corner. It is a physically bigger breaker, but still just 50 amps, for my stove. That is the breaker everything worked fine on.

Reply With Quote

Reply With Quote