Originally Posted by

DiabolicZ

So my daughters were watching a movie last night. I went out to weld in the garage. My oldest comes out after I made a tack weld. "Daddy! Something is happening!"

I go inside and she tells me that the TV picture was going crazy and there was a loud buzzing sound coming from the stereo speakers.

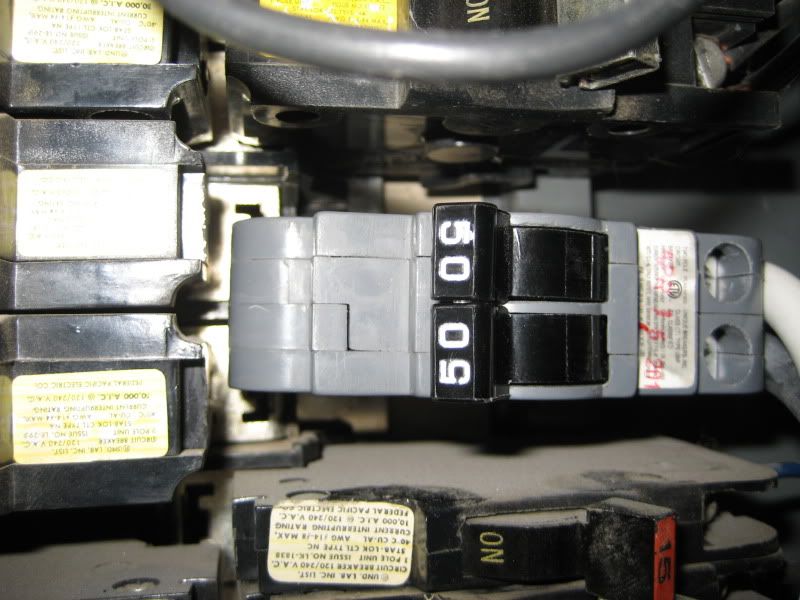

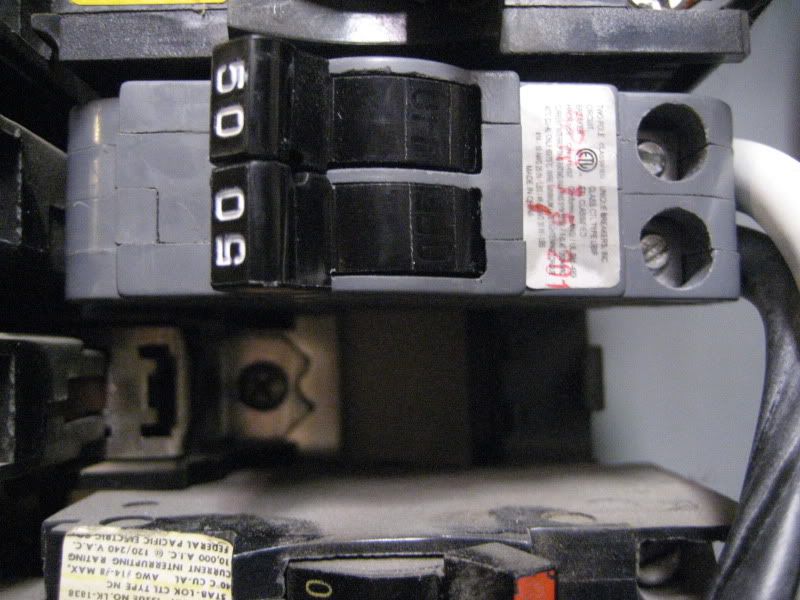

I have this machine on its own dedicated breaker.

Yes I also think if you ground the HF bolt it will stop all the buzzzzzing. My PP50 buzzed the TV in the office till I grounded it.

P.S. it drove my wife crazier in the office doing bills and talking to customers on the cordless phone.

SHOP SETUP

Esab Migmaster 250

Everlast PowerPlasma 50

Miller Dynasty 200 DX TIG

CNC Express SQ Mill

CNC Lathe 1236

Plate Shear 12"

12" Slip Roll

4 Ton Notcher

4 Ton Hand Punch

52" 18 Gauge Foot Shear

48" Pan & Box Brake

Spot Welder

50" Slip Roll

English Wheel

Bead Roller

Planishing Hammer

60" Hand Brake

7" x 12" Bandsaw

Hand Tools

Shop (TOO SMALL !!!!! )

I don't owe anyone a dime, but I get paid to lay them down

Reply With Quote

Reply With Quote