Right now here are my gauges are currently set up:

I had something set up in my center dash compartment like this:

Sorry for the crappy picture but i had to take it from a video.

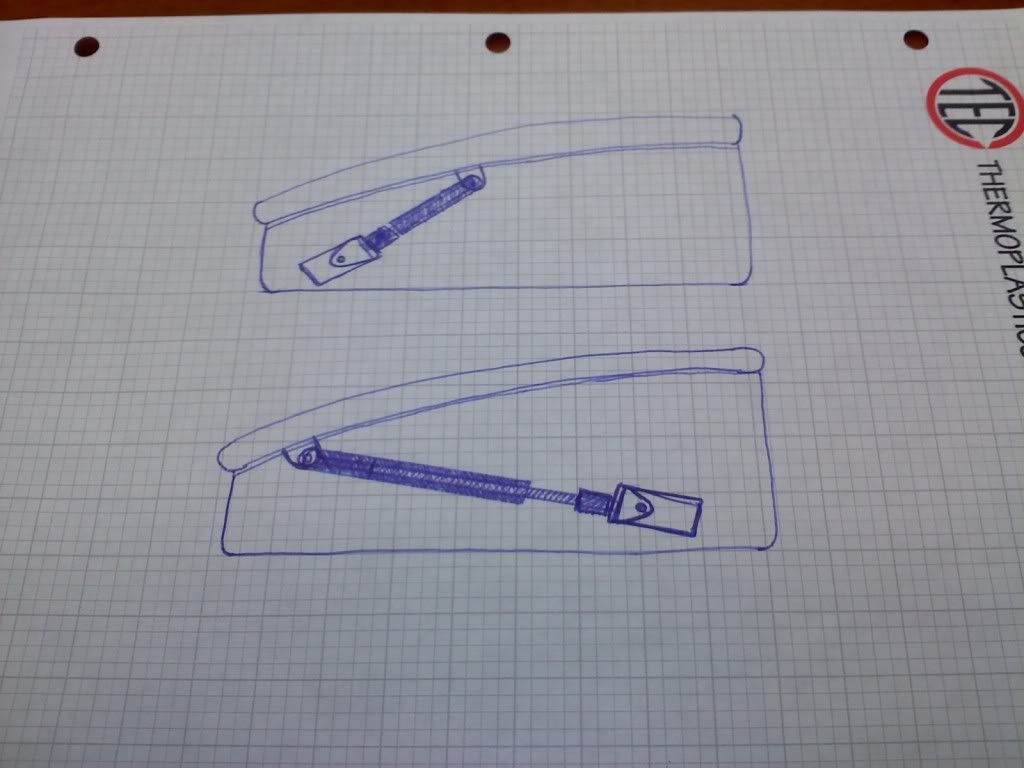

I want to do the same thing except that one is stationary and i want it to open and close. I have an idea i want to do drawn down at work that i will upload tomarrow when im there. Ive been thinking about this idea for about a year and its the only thing that i think might work. An actuator is to big for the area i have to open it. Any suggestions are welcome as i havent really been able to come up with something that amazing.

Reply With Quote

Reply With Quote