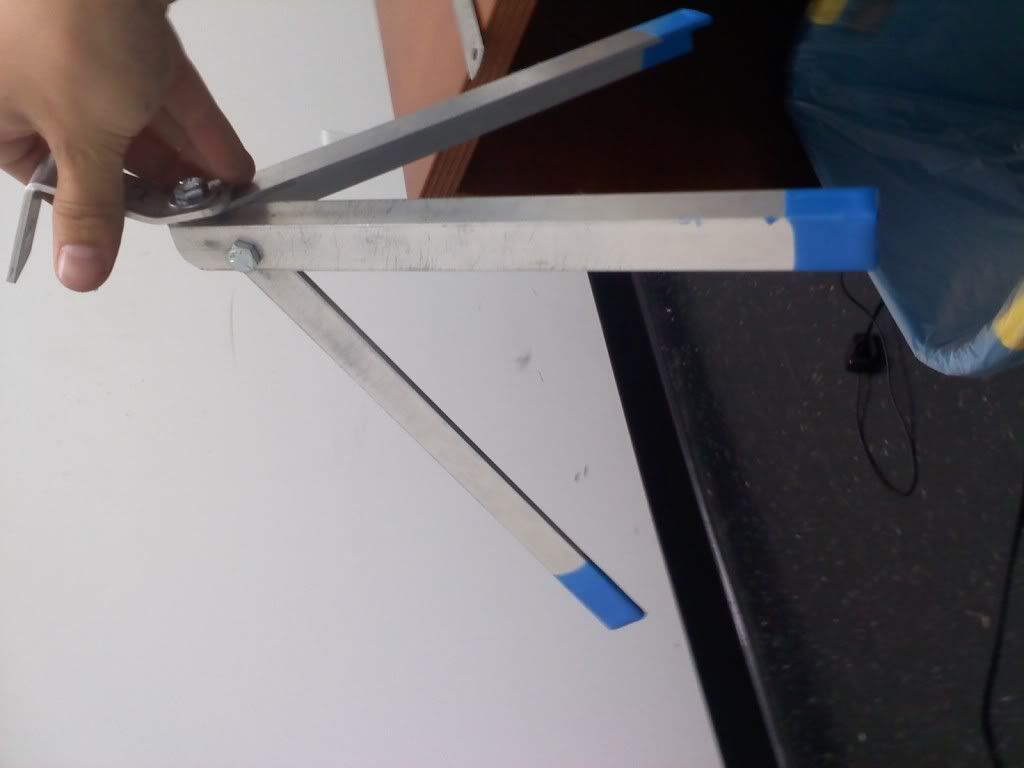

Since I didnt feel like asking around for a tri pod at work, i decided to build my own. Basically is uses .75" angle aluminum that 1/8" of an inch thick. I used two bolts to make the legs go out like a tri pod and a 1/4-20 bolt to hold the camera in place. Altogether it took about 30 mins for me to make. One thing i would have done differntly is to make sure the angles dont interfere with each other so it would fold up. The top part is made out of 1" x1/8" aluminum that i bent to shape. Here are some pictures:

Reply With Quote

Reply With Quote