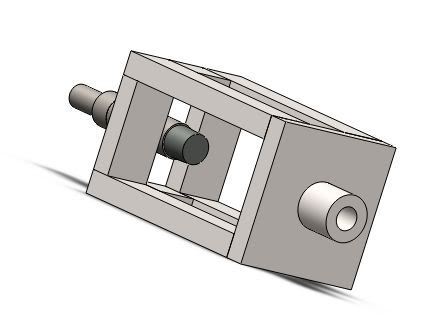

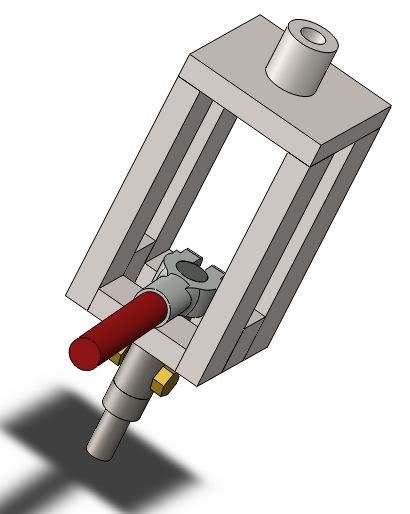

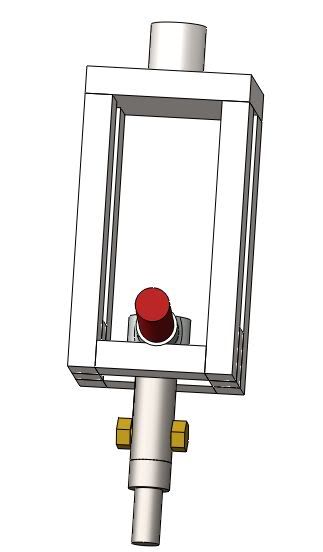

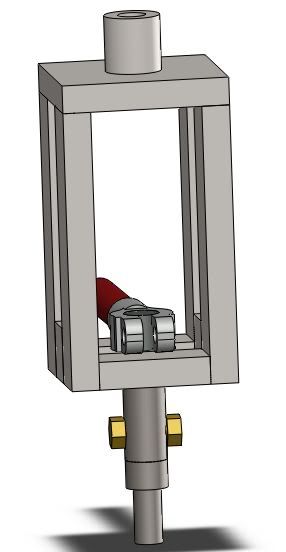

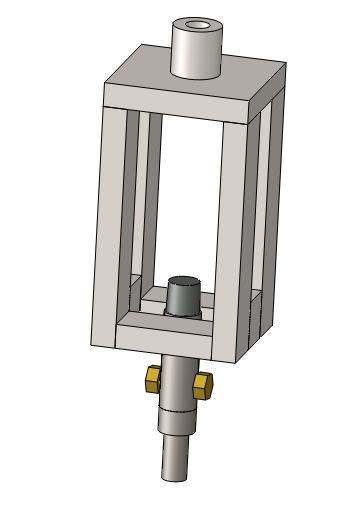

Here is a post puller I will be fabricating over the next few weeks in order to see the force required to pull a terminal off of a battery post using various torques for the nut and bolt. This is a CAD'd version and will update as I build it. Basically it will be attached to a pull tester and it will measure lbs till fracture or release:

Reply With Quote

Reply With Quote