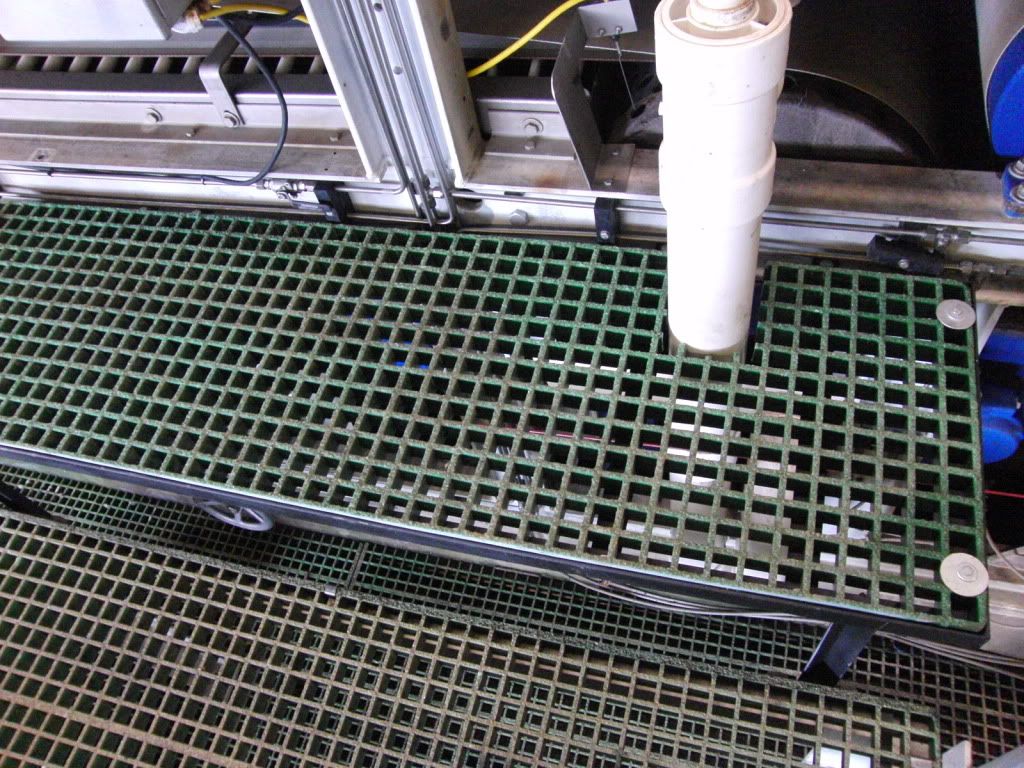

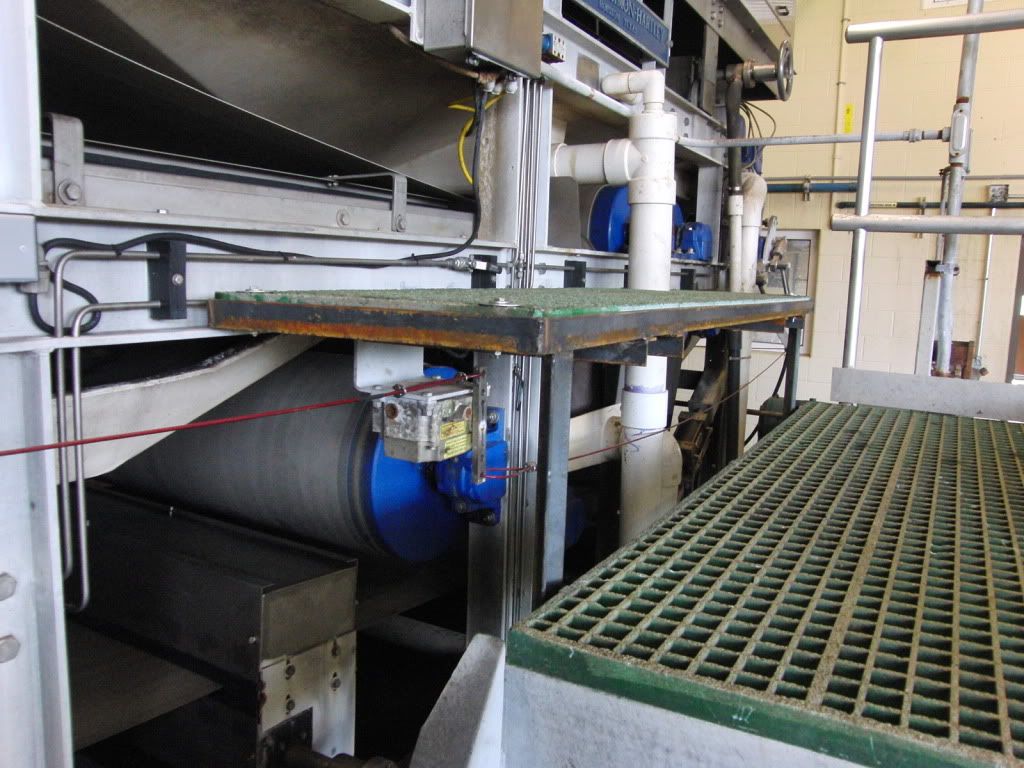

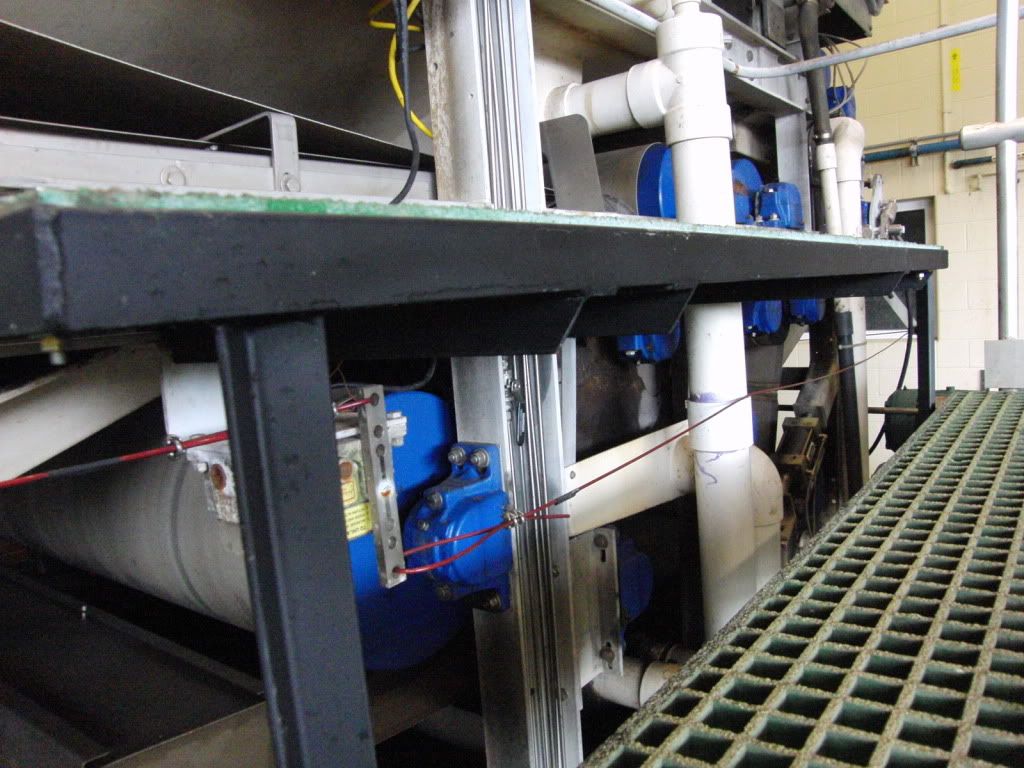

I had plans of posting some more projects, but haven't much time to work on anything. Anyways, I work at a waste water plant and get the chance to built stuff every now and then and had the chance to fab up a walkway addition to fill a dangerous gap between the original platform and the poo pressing machine as I call it. The gap had been there for years, but there was a 2 foot diameter pipe between the press and the steps, so it didn't seem as bad.

I used 1.5 inch by 3/16 angle steel and cut a piece of scrap fiberglass grating. Its amazing how strong the grating is by its self.

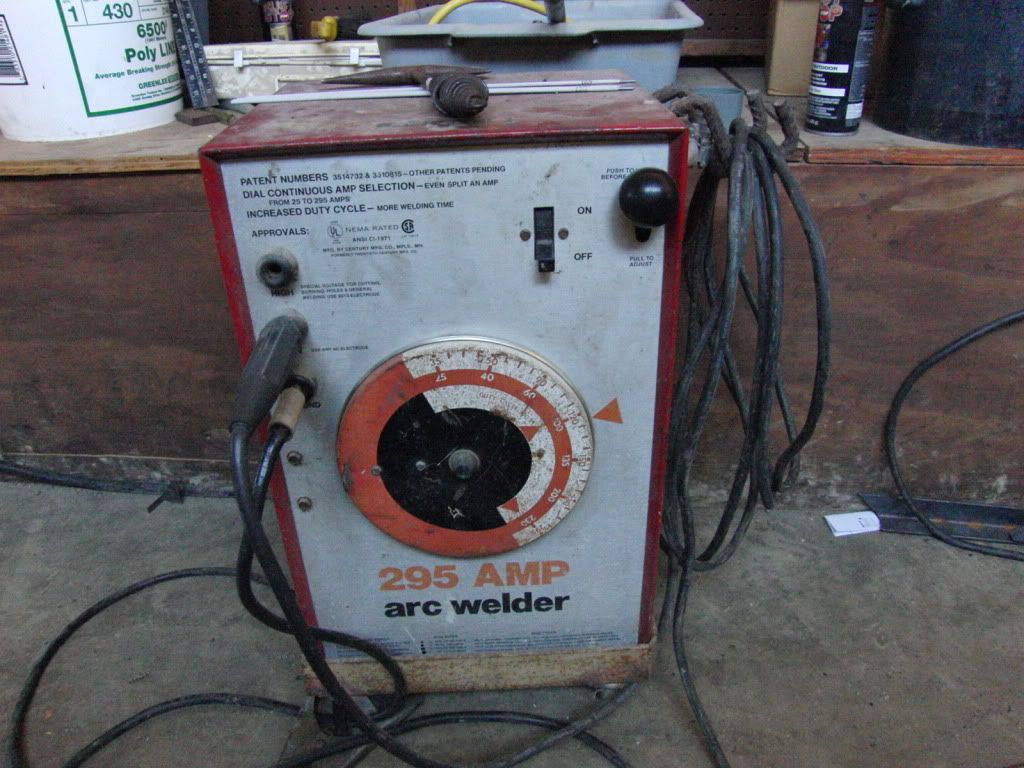

I used an old Solar ac only stick welder that runs on a whopping 200 volt instead of 230. 6011s are a pain to use with it, but 6013s still work.

I used existing bolt holes because I didn't want to compromise the heavy zinc coating on the steel frame. It was a bit inconvenient, but ended up working out quite well.

I sandblasted and used a heavy duty tractor paint hoping that it will last for a few years. That whole area gets exposed to some nasty stuff that eats paint like crazy.

Overall, it worked out quite well and my boss was happy.

Reply With Quote

Reply With Quote