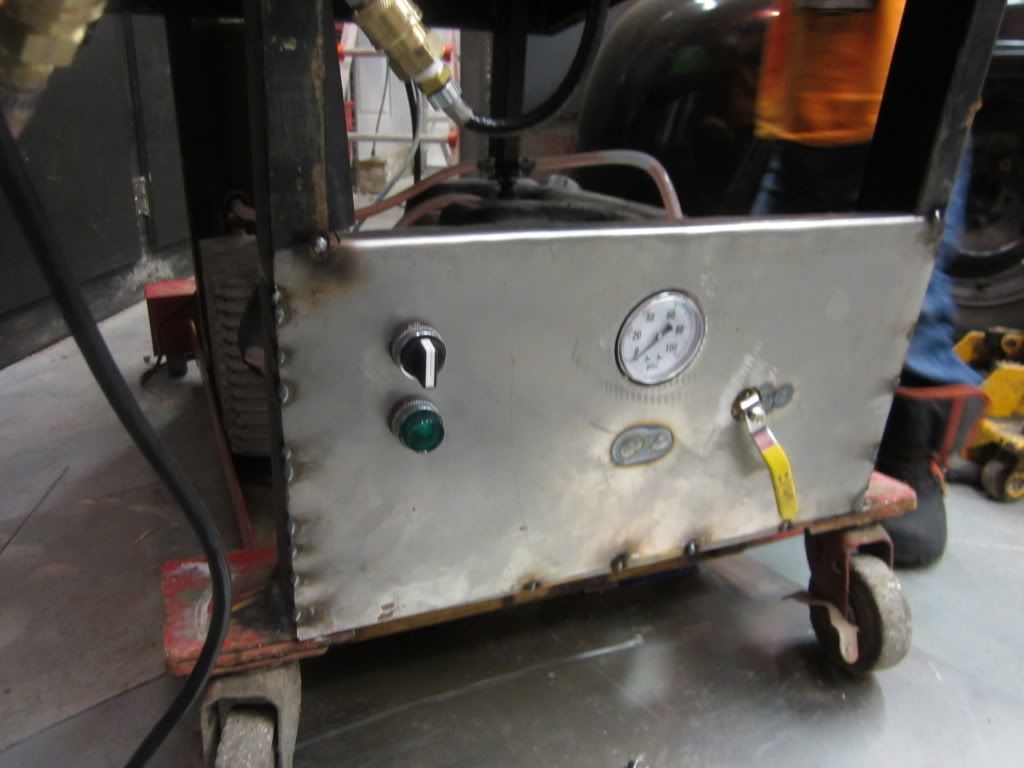

finally had time to finish my cooler/welding cart project, the cart is made with salvaged scraps i has lying around, the bottom part is actually a bottom i built centuries ago for my snap on bottom tool box, didn`t need it anymore so figured i might as well use it for something else, couldn`t find a pro con pump in my area so i used a 115 v sprayer pump, tank is out of a golf cart, condenser out of a 89 crown vic, built in 220v extension cord with two 115 plugs, one is used for the cooler, i still have a few other things i want to add, i have a 115v cord reel i want to add and a few hooks ect.

Reply With Quote

Reply With Quote