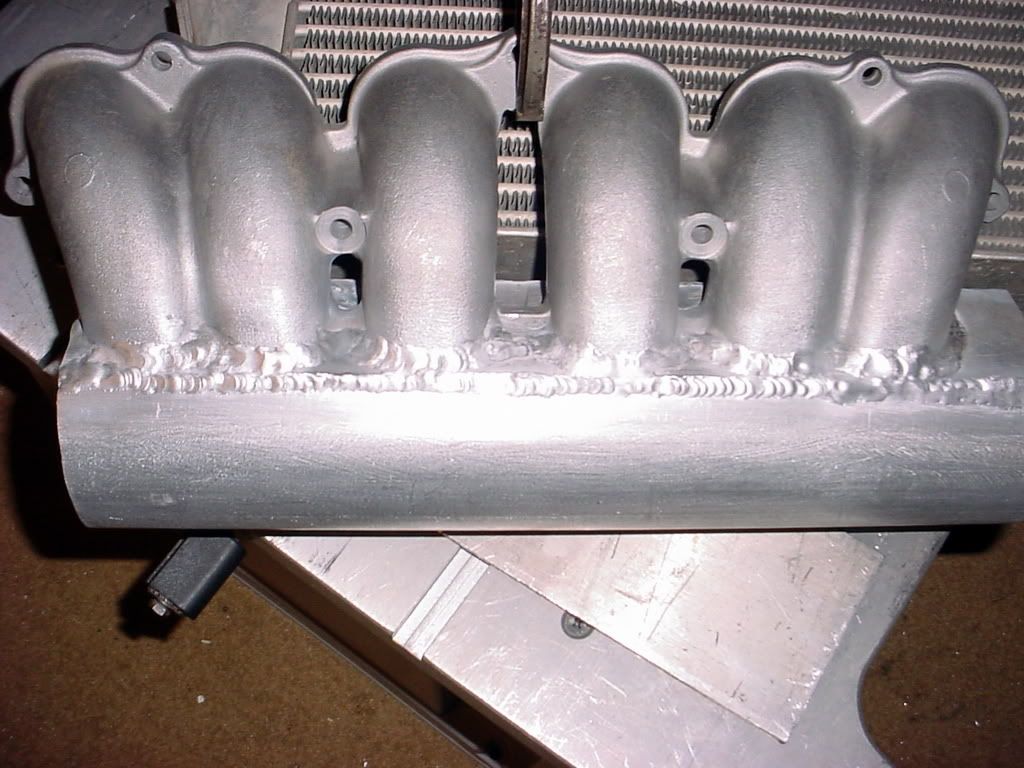

Ok here is my noobie Tig skills...don't laugh too hard

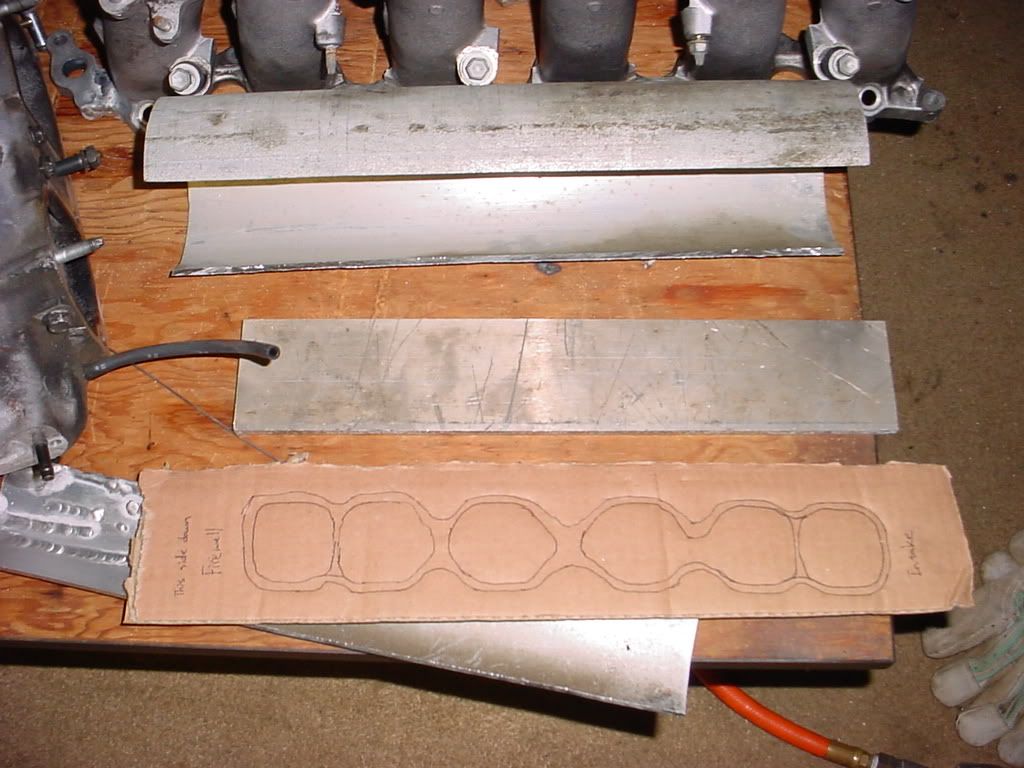

Using this

Practices...notice this is all the practicing I have done...maybe 15 passes.

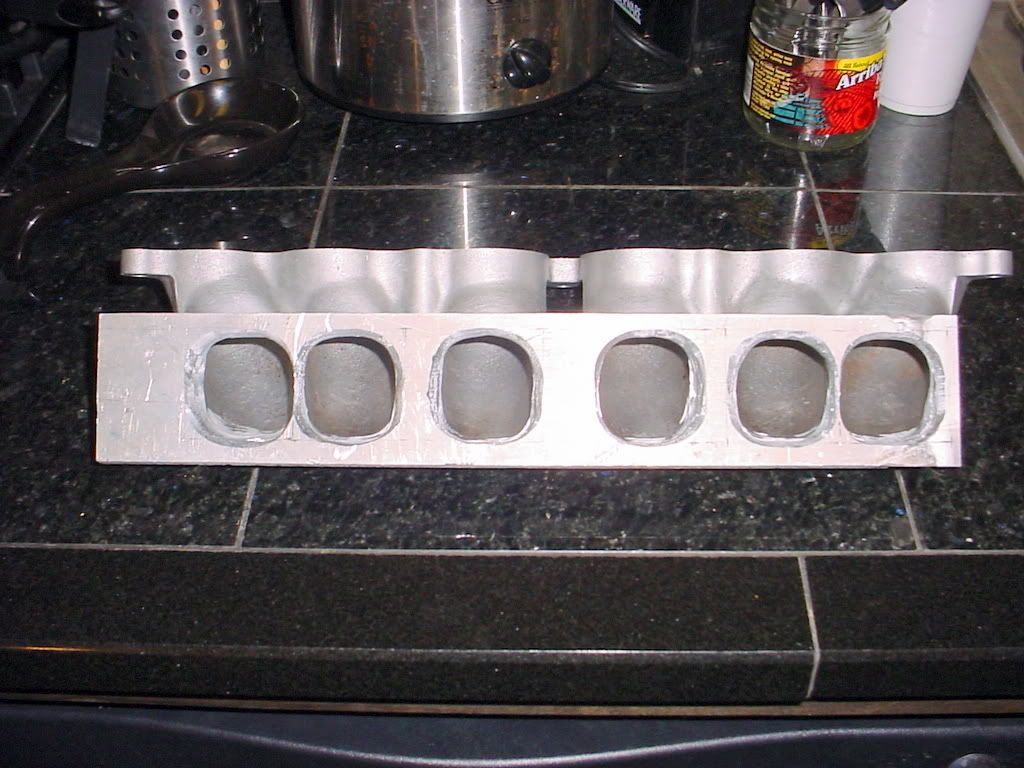

Ok I cut the flanges off this intercooler and then rewelded them at different angles to fit my new 2JZGTE project.

Before

And after

Reply With Quote

Reply With Quote