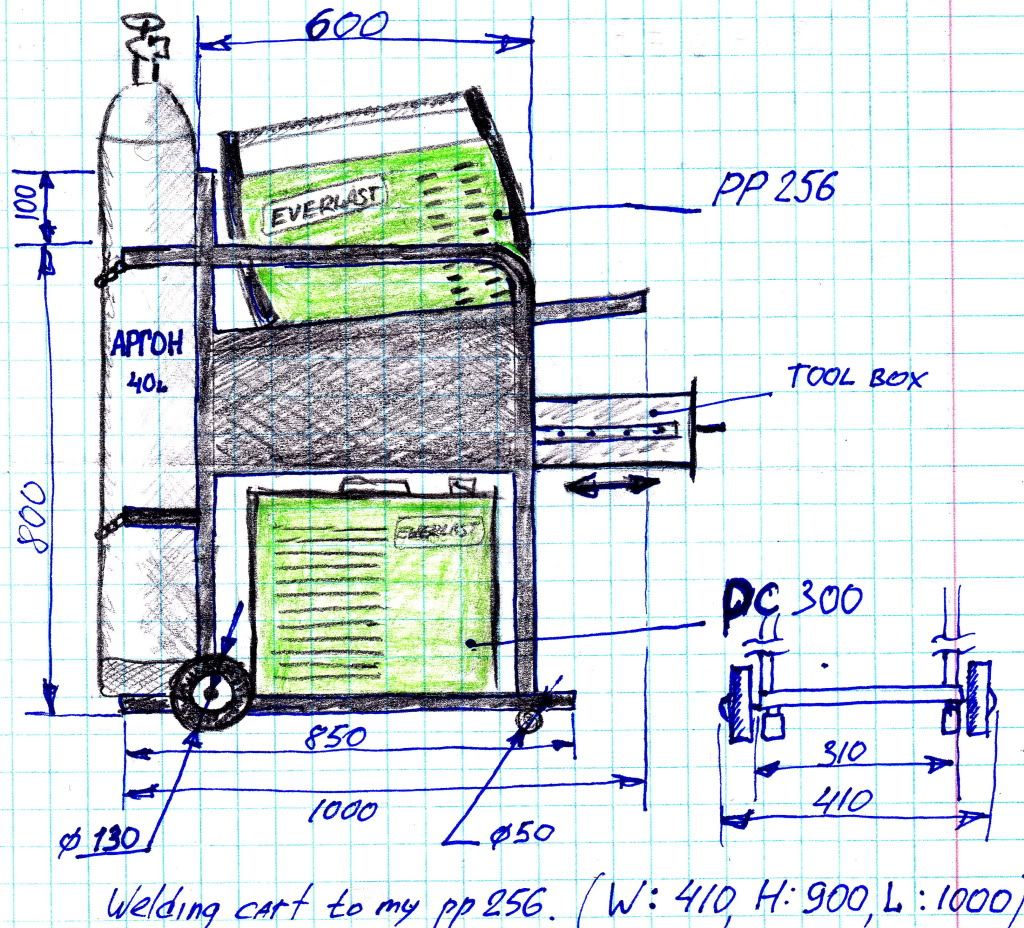

рр256 and рс 300 at me while is not present, I work in the sizes which to me has given CGCINC ( thanks Mike)

ALL SIZES ARE GIVEN IN MILLIMETRES!!!!!

Materials used: a square tube 15x15,10x20,20x20mm,metal sheet thickness of 1.5 mm,stainless steel rod of diameter 6 mm.

Tomorrow I will lay out the first photos.

The preliminary sketch

ALL SIZES ARE GIVEN IN MILLIMETRES!!!!!

Reply With Quote

Reply With Quote

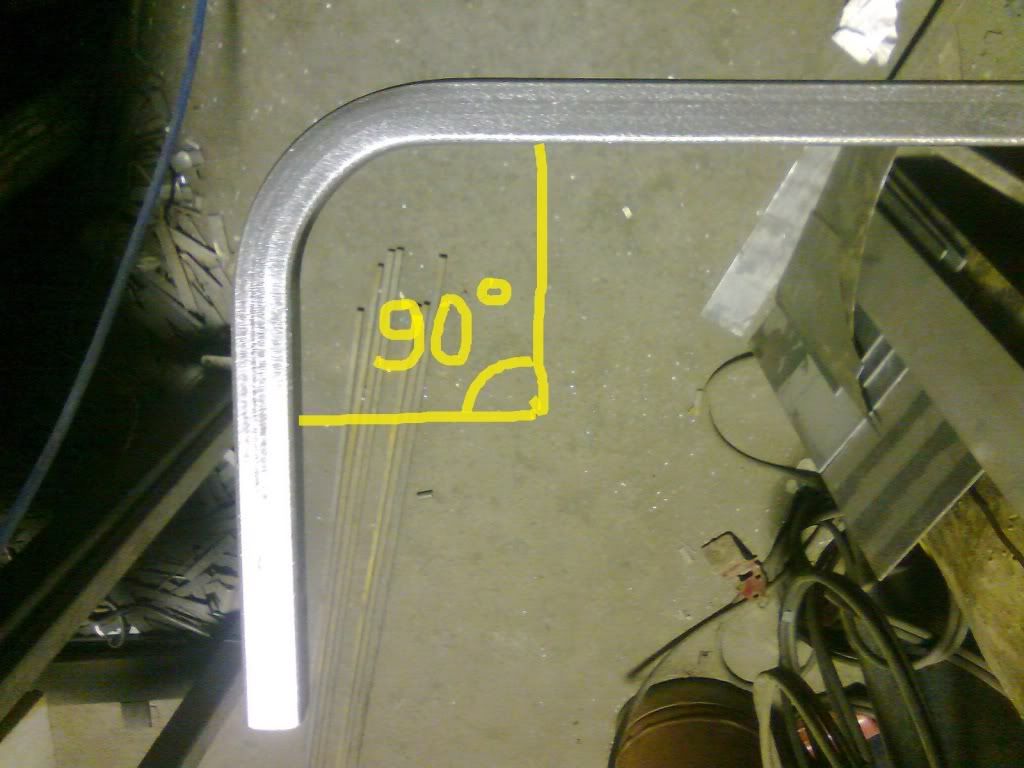

Today I have constructed a cart frame.

Today I have constructed a cart frame.

Alex, when you have overstock give me ring!

Alex, when you have overstock give me ring!