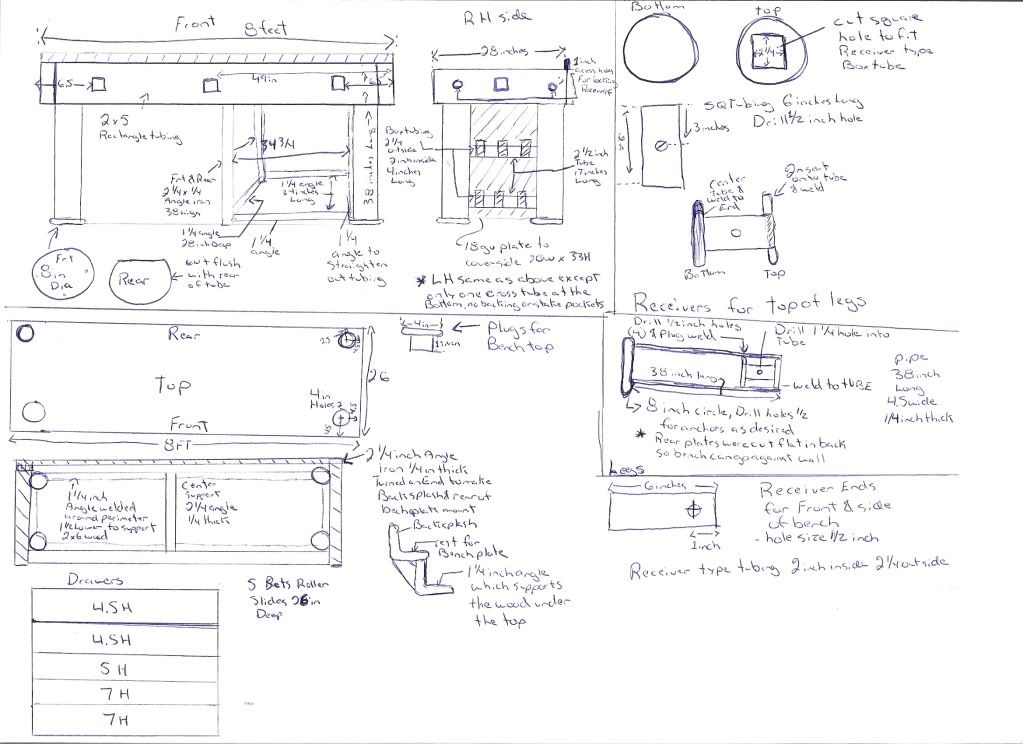

Hey guy`s, here`s my little project! i`ve needed a workbench for years now,and now was the time for the build, been scrounging up steel for the build for about a year now.I only have a 2 car garage so space is everything, my idea was to use square tubing, just like a receiver on a truck and have my vice, bench grinder and some of my metal tools removeable from the bench when i don`t need them, I also do lots of small engine repair and lots of time need the complete bench for a repair and the vice is just in the way.If you also look at the front beam the two end pieces are not Veed in nicely and welded up, this was an idea i came with during the build after i initially veed the steel, I also want to incorporate a sheet metal bender which would quick attach to the bench, i can then use these pockets to attach my bender. The top of the bench is 12 guage steel, if your asking why i put wood underneath it ,its because it takes the thud sound when you drop or move an object on the bench plus the top does not sag in, the wood is glued to the bench and then to the top.The drawers were going to be steel but opted for wood because of equipment malfunction.The empty part beside the drawers is for tucking in my welding table. attached is a rough blueprint of the material and measurements of the bench

before:

[IMG]http://i925.photobucket.com/albums/ad97/charger891/IMG_1215.jpg[/IMG

Reply With Quote

Reply With Quote

)

)