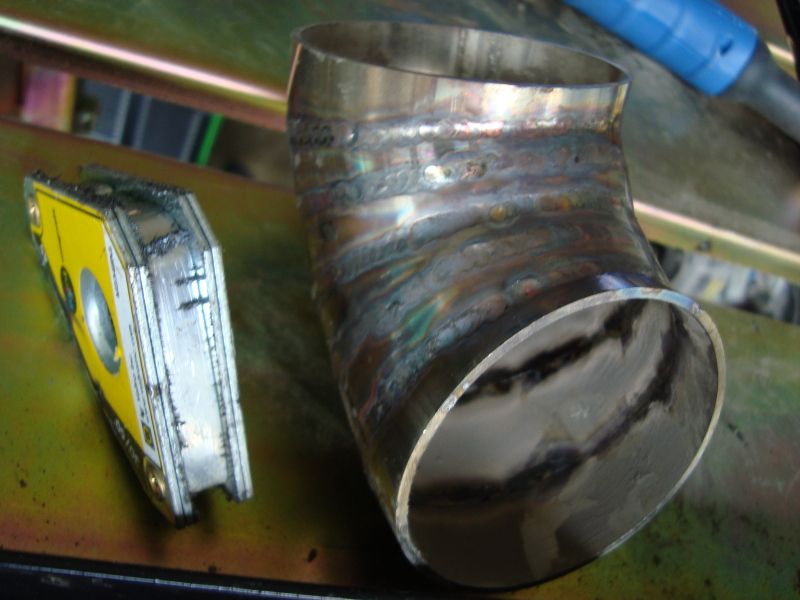

My last post was horrible I think everything went wrong on my welds plus its been almost a year since I welded anything 0_0. I had bad fitment, no back purging and everythning. I got great advice from guys on the forum changed a bunch of stuff worked harder to get the right end results and this is what I got. (Took forever because engineering school is something else)

Fitment was KING in this welding. I cut them clean on a band saw and then sanded the heck out of them. The pipes were so close I didn't even use filler ....... Well my learning curve hasn't got to where I can use filler rod effectively. I having trouble finding it comfortable to move and add at the same time. Probably need more adjustments on my welding table or position.

I listened to guys on the forum and used Solar Fulx type B. I got it on ebay because I wanted a small amount to test and it is BA!!! Sure beats using back purge because the pipes I weld are so small not sure how I would back purge effectively?

Everything else was the same got good heat from 55 amps DC no pulsing or fancy stuff. Well didn't use it because I not sure what to set it to yet.

Oh my welds got some burned dirty stuff because I got supper excited and got started with out grease removal on the pipes. The grease came from lubricating the band saw to cut it. Oh well one more thing to remember when I get good cuts again.

Materiel is 0.65 straight pipe 2.5 inches diameter. Cut on one side 15 degree angle and other is a straight cut. I added them together to make a 90 but the gradation of the bending is not sufficient for me. I want more gradation so I will change the angle to get more bending out of it.

So far its not bad as I welded I figured some stuff out and it got better progressively. Please no bashing me this is only the second pipe I attempted to weld and happy I even was able to get this far !!!! I am going to try harder next time and do better so all my welding looks better. Good welding all my forum people !!!!!

Reply With Quote

Reply With Quote