Hey guys -

It's about time I posted another project up, so here is one. This is an aluminum rear suspension of a mountain bike I repaired for a customer.

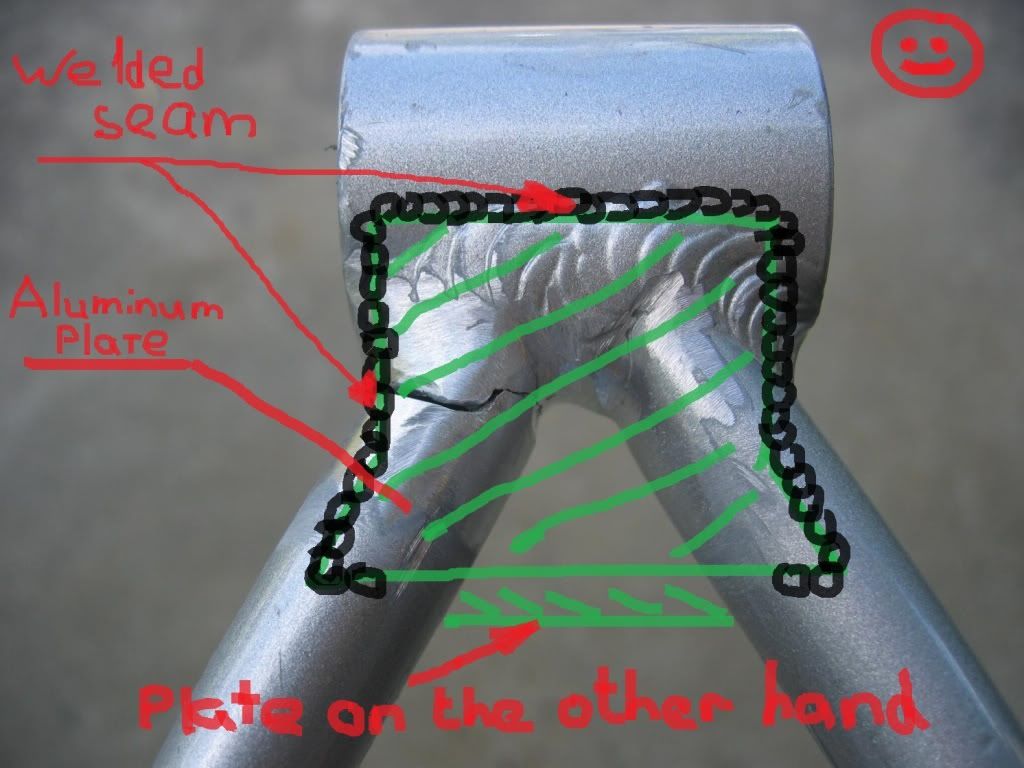

It is tubular aluminum, probably about .065" thick, and it cracked where one of two slender tubes met a large, thicker aluminum piece.

It cracked in the heat affected zone of the original weld. It is likely 6061-T6 (popular heat treated alloy for bicycles... in fact I think it might have even said so on a sticker.)

My thoughts were, I could repair it to its likely original strength, but am probably not going to do any improvement on that, because the heat affected zone will still exist in the tubing right next to the weld. That said, I would do the best I could, prepping it well, ensuring adequate penetration and thickness where welded, and an even (gradual) transition of thickness from one piece to the welded area to the other piece, focusing on leaving no stress risers.

-Before welding-

-Prepped-

I used a flap disc, evenly and with a very light touch so as to not excessively thin the tubing. Note also that I left an area where the pieces would "key" together to ensure proper alignment, although did generally remove the other likely contaminated, cracked faces aside from that. That gave me the best weld quality, without going to a huge unnecessary hassle of aligning the pieces.

-Welding setup used-

Note: 1/16" 5356 filler rod ready to go. Also, sometimes with painted parts, there aren't a lot of places you can ground to, and you do what you can.

-After welding-

Reply With Quote

Reply With Quote