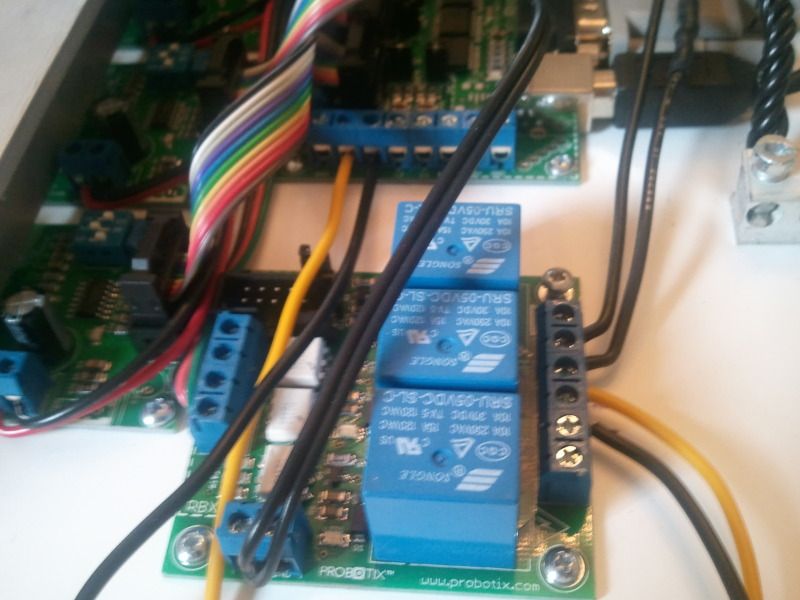

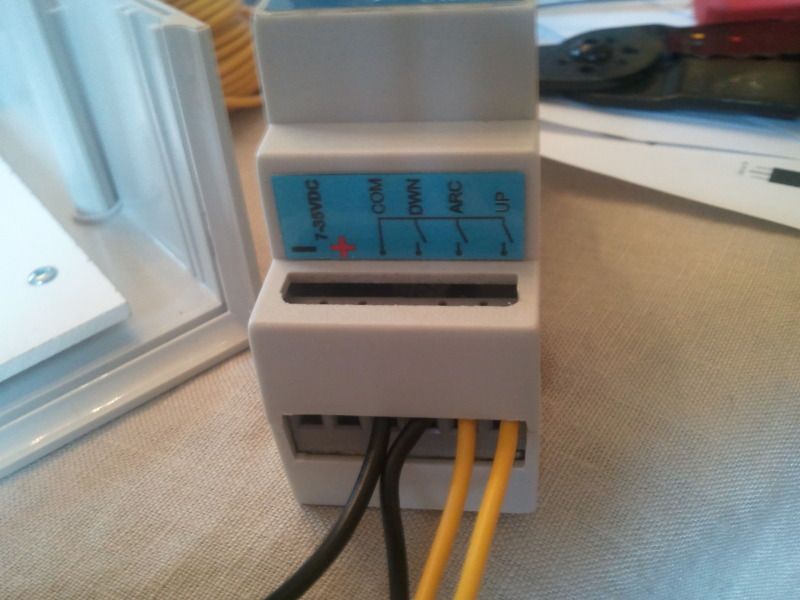

The table I built on my own. I had originally planned to follow the plans from the kit I ordered. I purchased the carriages from No Sleep Studio. He gives you a list of materials you will need (gear rack, bearings, hardware, etc) after you purchase the carriages. He has a print for a table on his forum. No Sleep sells parts and you build your own table with their plans and build of materials list. The B.O.M. gives you links and part numbers for all the parts you will need. I went with Probotix 4 axis monster kit for my electronics. A lot of people go with CandCNC.com pre-wired RTR kits. I know there is a popular Australian company that sells the motor kits as well.

http://www.needfulthings.net/host/no...udio/index.php

Shop Droids Forum

http://www.needfulthings.net/shopdroids/forum/index.php

Reply With Quote

Reply With Quote