Anybody got any good ideas for a holding fixture to join short pieces of filler rod?

Anybody got any good ideas for a holding fixture to join short pieces of filler rod?

Everlast PowerTig 200DX

Snapon FM140 Mig

Purox Oxy/Acet Torch

Coleman 80 gal. Compressor

7x10 Mini Lathe

Craftsman 12" Bandsaw

Lots of litler stuff

A pair of "helping hands" might work. Those weighted stands with two jointed clip arms. They've worked everytime I've ever needed to join electrical wire of just about any size 10ga or under so I dont see using them to hold filler wire being too hard. You could also try laying them in an in 90¤ trough made by two ceramic blocks.(Used that type of setup for small joints before.)

Yea, Im kinda thinking of laying it down inside a 90 degree angle with a hole or gap in the center.

Everlast PowerTig 200DX

Snapon FM140 Mig

Purox Oxy/Acet Torch

Coleman 80 gal. Compressor

7x10 Mini Lathe

Craftsman 12" Bandsaw

Lots of litler stuff

No need for a fixture just touch them together and tack.

This past weekend I was fabricating/welding up a new collector back, side exit exhaust for one of my son's 07 cbr600rr.We also installed a cbr1000 subframe. The whole bike will get painted soon.

I had some short 1/16" tungsten on the bench that needed grinding. When I picked them up I grabbed a short piece of 1/16" 308L filler rod by mistake and sharpened it with the rest. Later on it wound up in my torch and I got a helluva surprise when I lit it up at 40 amps. It melted back to my gas lens instantly with a bright yellow light. No damage done, lesson learned.

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw

Everytime I try that they keep rolling on me, especially when the gas preflows.

Everlast PowerTig 200DX

Snapon FM140 Mig

Purox Oxy/Acet Torch

Coleman 80 gal. Compressor

7x10 Mini Lathe

Craftsman 12" Bandsaw

Lots of litler stuff

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw

Good idea! I'll try it.

Everlast PowerTig 200DX

Snapon FM140 Mig

Purox Oxy/Acet Torch

Coleman 80 gal. Compressor

7x10 Mini Lathe

Craftsman 12" Bandsaw

Lots of litler stuff

Wood doesnt contuct elec

Everlast PowerTig 200DX

Snapon FM140 Mig

Purox Oxy/Acet Torch

Coleman 80 gal. Compressor

7x10 Mini Lathe

Craftsman 12" Bandsaw

Lots of litler stuff

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw

zoama I'm still laughing that is classic Gas stainless arc welding lol. I could picture the look on someones face when the torch flared up.

Everlast PowerTig 250EX

Everlast PowerCool 300

Everlast PowerPlasma 70

Lincoln Powermig 215

Magnum SG Spool Gun

Don't jump on my Gomba

Links to my welding projects > : Spray Arc with the 250p : Coldsaw Stand : Welding Cart : Heavy Duty Rolling Shelf : Taller Bandsaw

2013 250EX : SSC Pedal : I-MIG 250P 20' Profax gun : Power Plasma 60 p80 torch : 3M Speedglas 9100XX : Evolution Rage 3 DB cold saw

LOL at the stainless tungsten electrodes. That could make for a nice little prank for someone.

Anyways, back on subject. I've welded together a bunch of pieces of 1/16 308l filler by just taking on a piece of aluminum. I used something like 10 or 15 amps and held the 2 pieces with my left hand. I don't have to worry about being fried by a high frequency start because I only have lift start. It works just fine once you find the right amperage.

Everlast lx225

Hobart Handler 210 with spool gun

Hobart Stickmate LX

Thermal Arc 400GMS

40 amp Northern Tools plasma torch

130 chicago electric tig welder

90 amp chicago electric flux mig

10"-22" Grizzly lathe

15"-5.5" Grizzly vertical end mill

In need of nice TIG machine. drooling over PowerTig 250ex

Just weld one filler rod "stub" onto any workpiece, which you need to weld with that type (alloy and diameter) of filler rod. Let the puddle freeze with the filler rod stuck in the frozen puddle. It will support the filler rod rigidly and make a good ground connection.

Grab your next filler rod stub (or even a fresh, full length, 36" long filler rod), but its end up to the end of the stub being held in the air by your workpiece, and fuse the filler rods together using your tig torch and low amps (throttling back with the footpedal is helpful, if your pedal range works at low amperages.) After your new elongated filler rod has solidified (and perhaps cooled down a bit, if you were thinking about grabbing it right where it was liquified), you are ready to continue welding on your workpiece.

Last edited by jakeru; 03-01-2012 at 05:24 AM.

'13 Everlast 255EXT

'07 Everlast Super200P

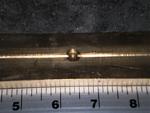

I took a piece of brass, (or it could be aluminum-bronze), and milled a channel with an 1/8" ball end mill. I made the channel about .150" deep and in the center of the piece I took a larger ball end mill and made a deeper area where I join the rods.

The deeper basin does a good job collecting and holding argon but I made it a little too big and deep. I made it about .200" deep and about 3/8" wide. It only needs to be a little wider and deeper than the channel.

Other than needing something to either hold down or prop up the other end of the long piece it works pretty good.

Last edited by Jetfire3; 03-03-2012 at 11:53 AM.

PowerTIG 250EX

Power Cool 300

Hobart 210MVP