This is something I have been meaning to try for a while now, and finally got a bit of spare time so I went for it. There are a few benefits to a twin scroll over open, but that is the long boring explanation. If you wish to read up on it, Google is your friend.

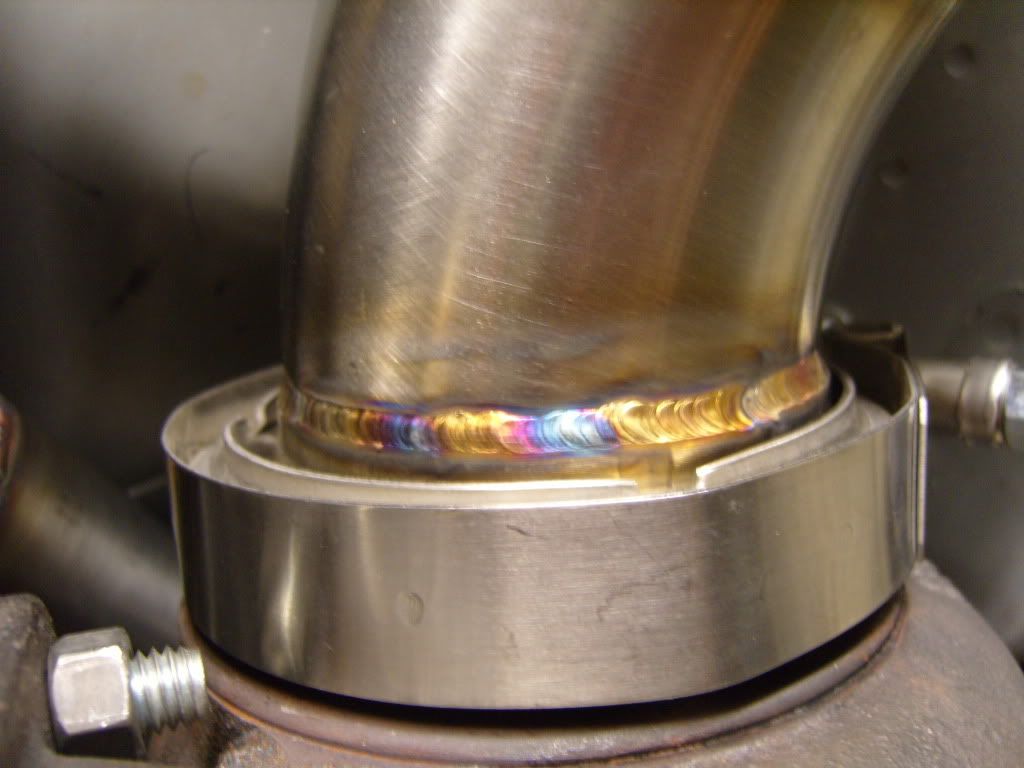

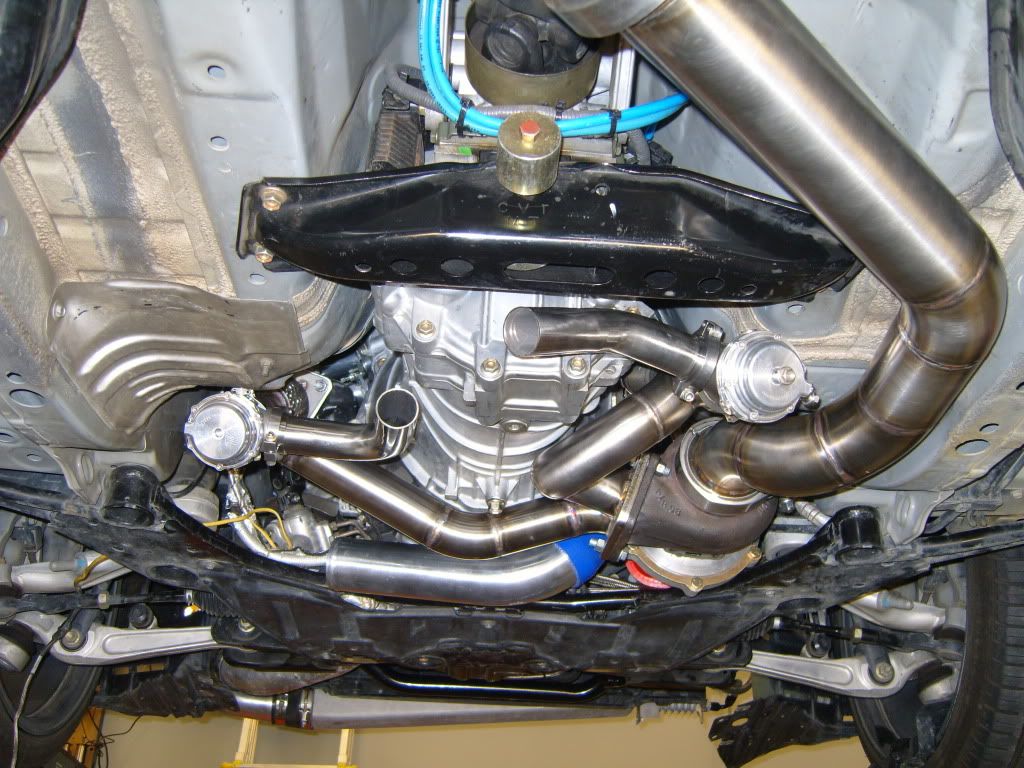

The idea here was to make it a very easy/simple to install/remove. The other very important thing is that the exhaust banks are separated all the way, and the exhaust piping length from header to turbo is the same (within 1/2").

Now on to the good stuff..

Passenger side section:

There is still a lot of room here:

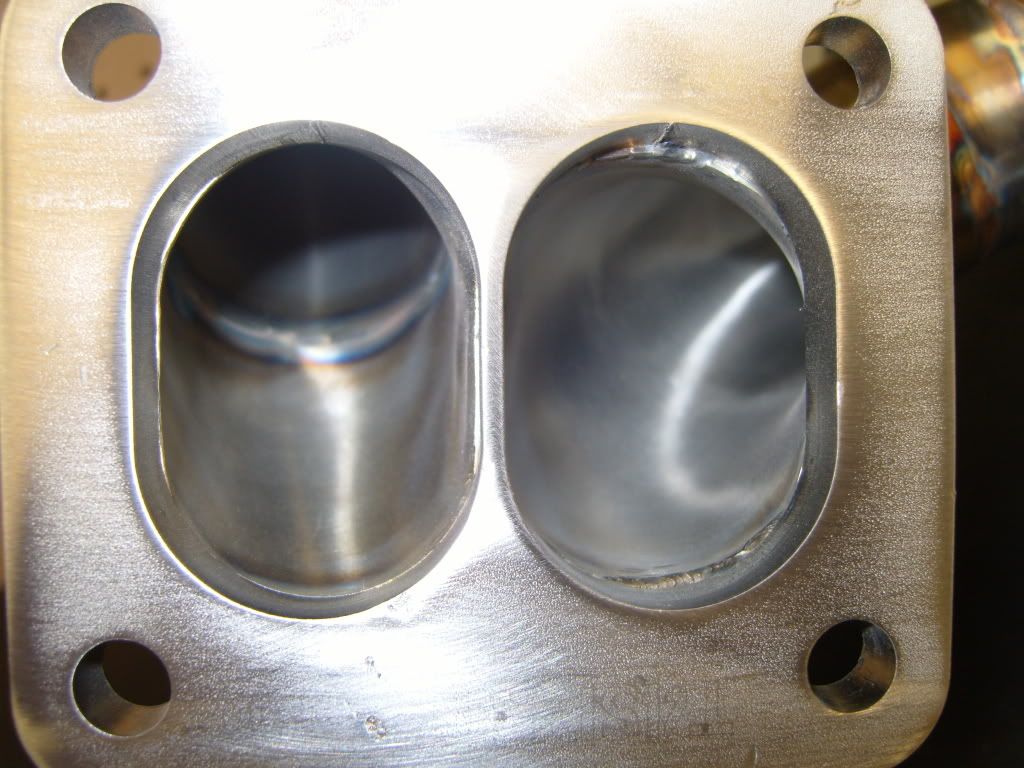

All new 66mm turbine wheel:

I will be able to use the all new Precision 6266 or 6766 T4 turbs, with the following a/r housing options: .84, 1.0, 1.15 and 1.32.

Reply With Quote

Reply With Quote