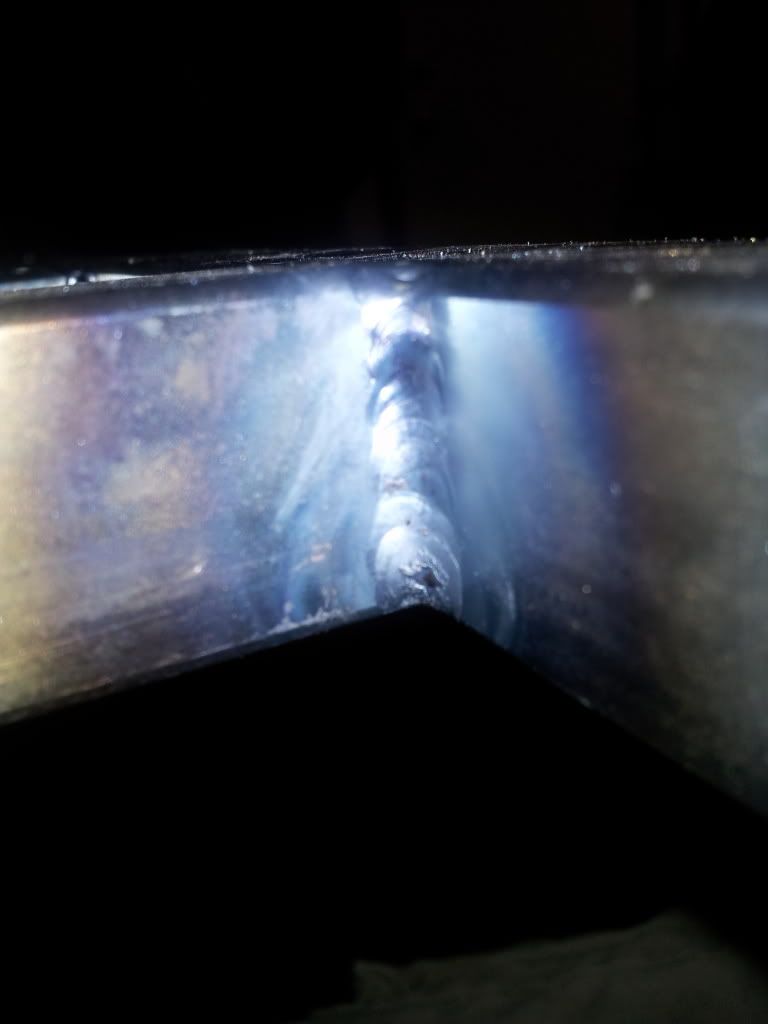

My harbor freight welding cart is too small for my 225LX. So I decided to build my own. I had some 1" Steel Square tubing left over from bracing the legs on my welding table. May as well use it to build my cart. Heres the base for my cart. Settings used was DC 88amps, 1 sec preflow 2 secs postflow 3/32 lanthanated tungsten 3/32 ERS70S2 fill rod, 8LPM with a gas lense and #7 cup. I still need more practice but I think my welds look pretty good.

What gauge sheetmetal should I use for the base? 16 gauge?

I'm almost empty on Argon so I think I'm going to upgrade from a 80cf to a 220 tomorrow.

Reply With Quote

Reply With Quote