Originally Posted by

sw2x

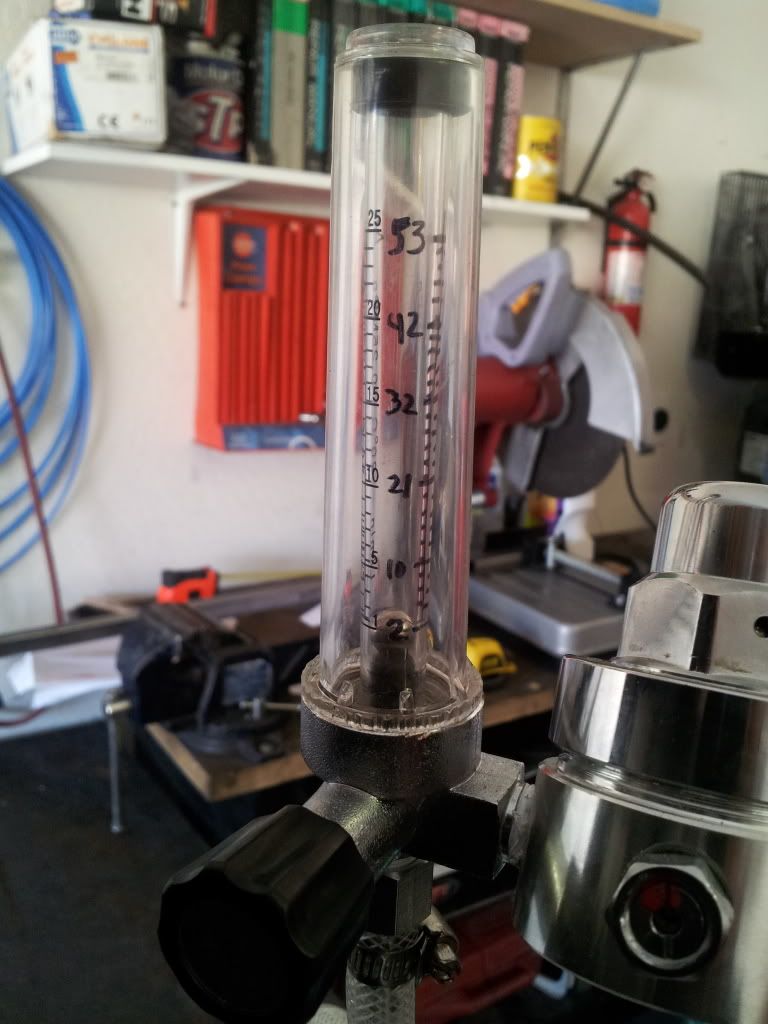

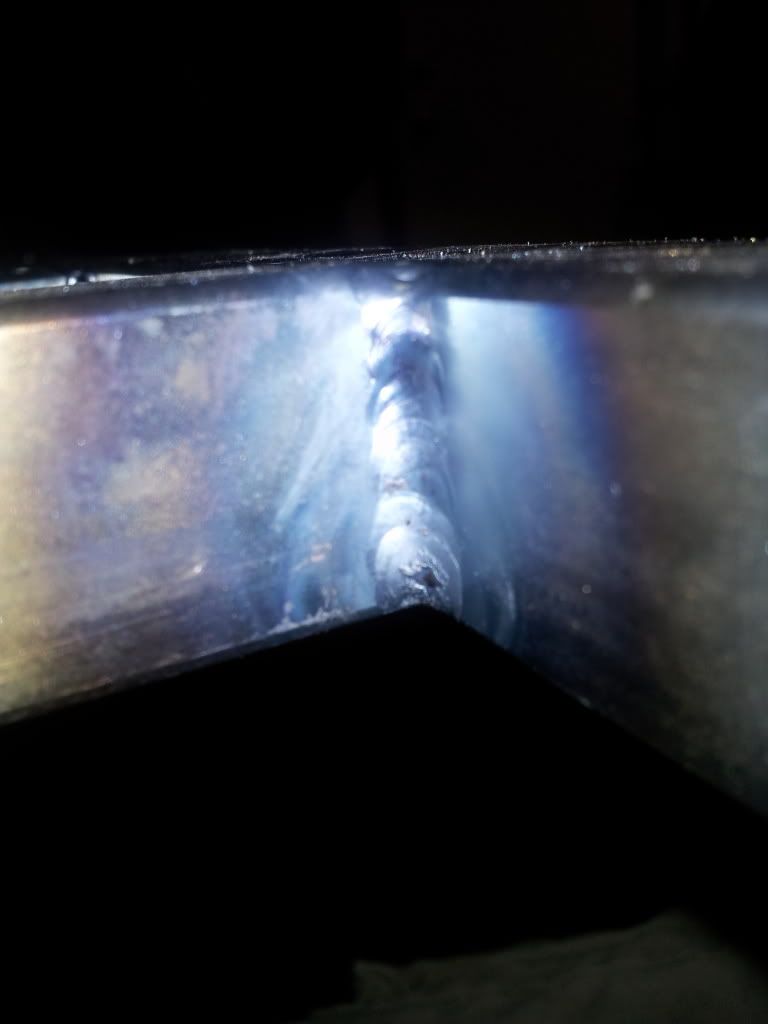

Heres the newest images of my welding/plasma cutting cart. I'm quickly learning how expensive this hobby is going to be. I need a metal brake because cutting steel sheet in a wood bandsaw with a metal cutting blade is not very exact. But I'm making due.

Once you get your plasma cutter, you can cut sheet metal. A metal brake is used for bending.

Good looking cart...I used the same large wheels for the back of mine, and it rolls around with ease, even when I take it out into the gravel drive. A suggestion might be to make a wider axle, and use spacers between cart and wheels, to give the top-heavy cart a bit more stability.

ken

Last edited by KSmith; 03-21-2012 at 08:06 PM.

UNT 520D plasma/stick/tig; Hobart Handler 140 Mig; HF 80amp stick welder; Victor O/A; 4x6 Horizontal bandsaw; Planishing hammer; & Stuff

Reply With Quote

Reply With Quote