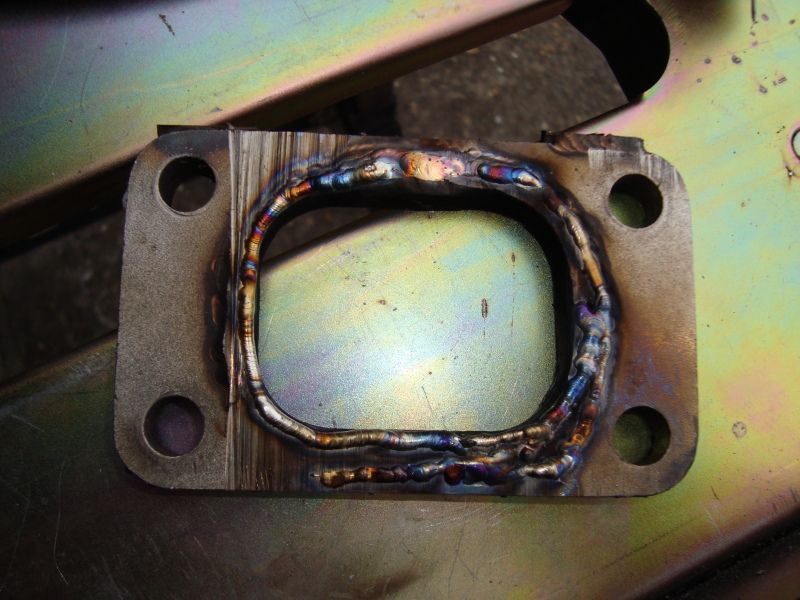

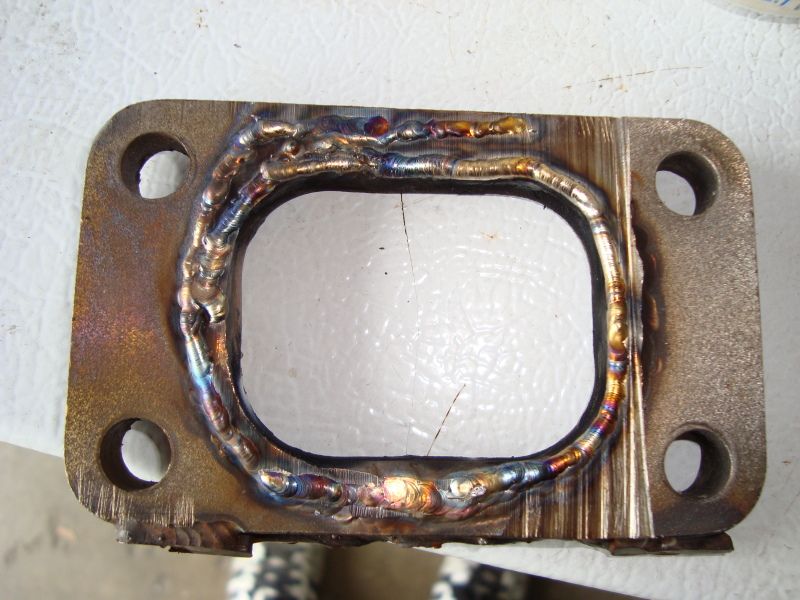

Hey guys this is my first attempt to use stainless filler metal. I am just welding on a scrap junk piece of turbo flange junk I cut off.

I cleaned my flange metal first with some tar and grease remover used for peeping cars for paint.

I got a sweet Chinese gas lens for the original torch that came with the my everlast welder. I cant wait to change this torch out for a weld craft torch or something more flexible and lighter. I think this is what really helped me get good color out of my welds. Almost forgot make sure you turn argon flow up more for use of a gas lense I set it something like 10 L/min something like that Ill go back home and look later.

I am use .030 Er316 weld wire for a mig as filler metal. I was told the silicone in the mig weld wire helps keep it cool.

I tried out pulse setting after really studying it. I left my sheet at home so I dont remember what I did to my machine. But it seemed to work very well.

I bought a cheapo auto dark helmet from harbor freight and it was good. But I decided to spend the 40 bucks more and get a miller pro hobby all black hood from cyberweld.com 80 bucks. It was worth it by all means.

I got plans to change out that horrible foot pedal from everlast too its like a giant heavy rock you need to climb up and step on every time you use it.

Anyhow here are some pictures right as my beads started getting tighter my neighbor asked me to help him with is BMW race car. I will get back in the seat for more practice after some test at school (I know the beads look horrible). The color is magnificent. Through my helmet I could see the colors change as it was cooling I am not sure if this is an affect of the gas lens(probably) but it was BA. I finally figure out that you actually had to dip the rod in the puddle .... sounds noob but its a lot harder than I thought. Then you need to back out the filler out of the heat area or it will just ball up and melt. Anyways hope this helps some people that are noobs like me.

Reply With Quote

Reply With Quote