I posted this in the chat lounge but I wanted people to be able to find it in a search engine if they want to try it themselves so Im posting it here as well.

I wanted a wood propeller but didn't want to pay for one so I decided to build one myself.

I started out with 5 pieces of 1x8 @ 6' long and glued and clamped them overnight.

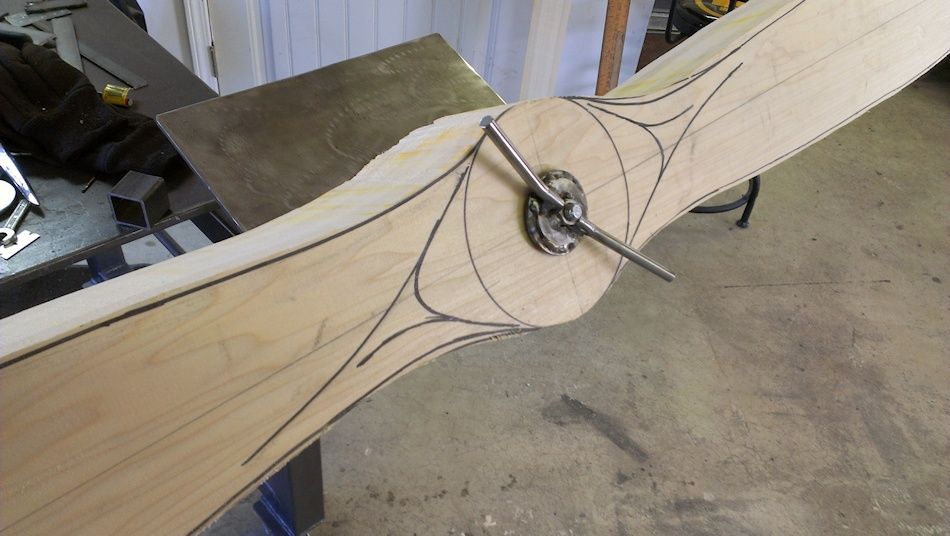

Then I made a mount to hold the propeller while working on it.

I used 1" tubing with a bolt welded to it and a nut with handles welded to it. The mount was welded to an adjustable small welding table I made to slide in the rails of my welding table.

Then I drew out the propeller on the wood and put it on the mount to cut the bulk of the wood off to get the shape.

I used a sawzall with a 12" blade to cut the rough shape.

Once I got it close with the sawzall.... I switched to a 4 1/2" grinder with some 60grit flap discs......you can't just tear into it, you need to "stroke" the wood so you don't gouge out huge valleys.

After the flap disc, I went over it with 100 grit then 220 grit sandpaper.

Then it is time to stain to color...

Next I made a 3" nose cap. This looks nice but it is also how I hold the propeller to the wall mount.

Reply With Quote

Reply With Quote