Originally Posted by

everlastsupport

sdr kel,

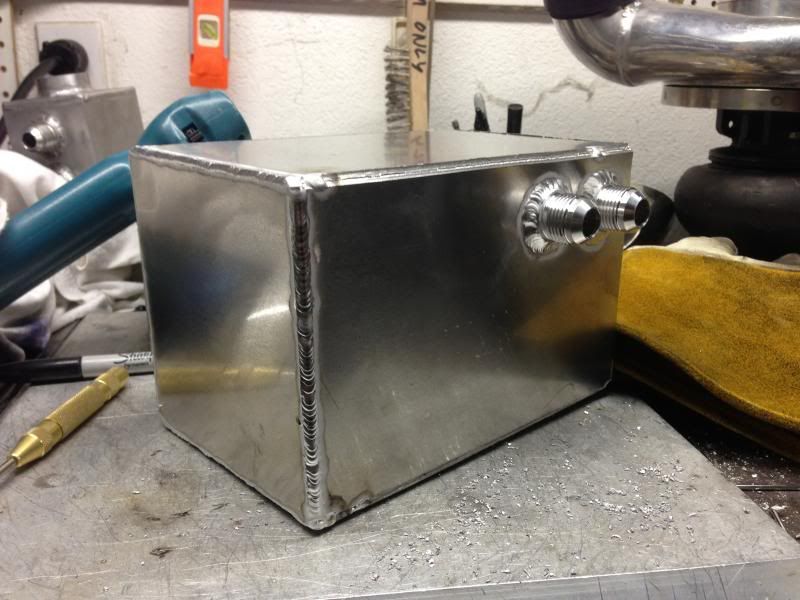

Thanks for coming back and sharing your Everlast experience. We sell a lot of welders and many people never make it here to the forum to share. I see your welds from the first picture to the latter ones improved quite a bit. Thank you for posting. It will inspire many others, that end up here to read, to give welding a try.

And to mention you are working with aluminum and our entry level AC TIG product (the 185) and doing basically what you can do with any of our higher end units with practice, should get some new people excited.

Reply With Quote

Reply With Quote