Originally Posted by

Trickle X

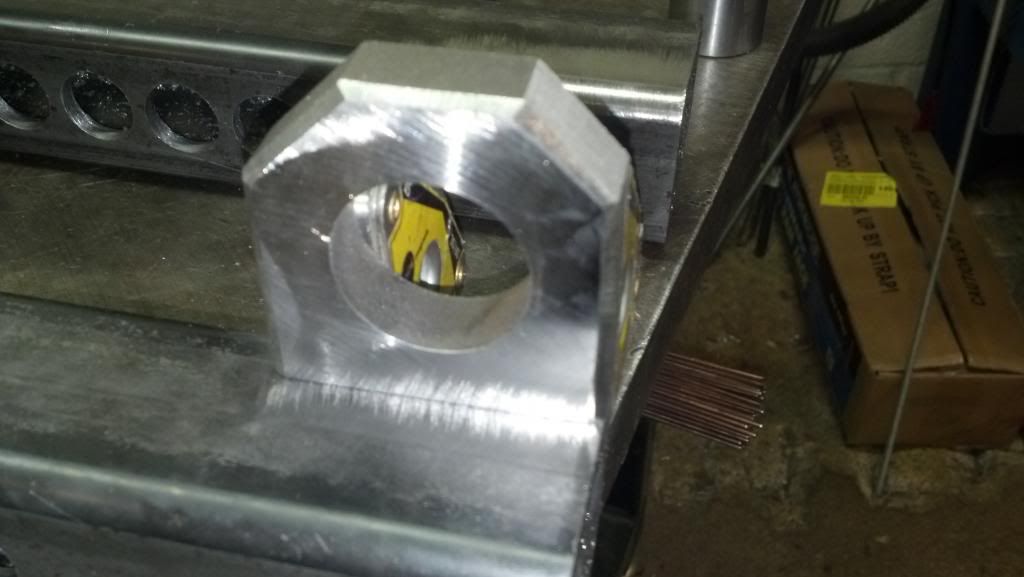

Thanks for posting the other thread! Yes you are correct, I just didn't have a lot of lathe time in at that point and wasn't comfortable in doing it that way. I also now have a bore tool for the mill and that would work like I used in my other thread to make a perfect hole for my fuel pump.

Yeah, I saw that in your other thread. Lots of ways to skin that cat. Another option is Rotabroach annular cutters, they make large holes withing the reach of a light drill press or mag drill. Not cheap, but worth it for a lot of jobs. Just in case others are looking to make something like this without a shop full of machines.

Did you buy or build your dies? I'm always on the lookout for a good source for bending dies.

Long arc, short arc, heliarc and in-the-dark!

Reply With Quote

Reply With Quote