You got it. To spray .030" that wire would be flying. Something like 500+ ipm would be required. There are formulas to calculate amps and wire speed. Stickout also affects it to some extent. Total weld power is amps times volts, so even if one is high enough, the machine may not be able to keep both in the range you need, when pushed to the max. It's never a good idea to run a machine at it's redline, if you expect it to last.

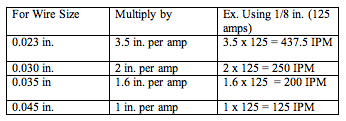

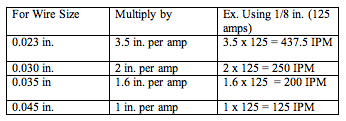

Here is an example chart for steel wire, aluminum is about double as I recall.

Long arc, short arc, heliarc and in-the-dark!

Reply With Quote

Reply With Quote